Pockets are the first thing to fail on a pair of jeans. Weak construction and poor materials can ruin your design's integrity and your brand's reputation for quality.

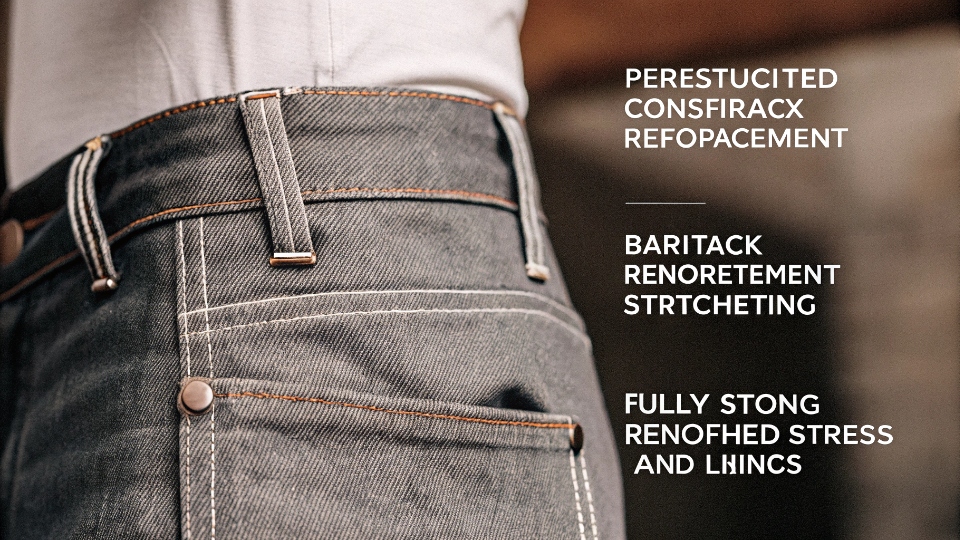

We build durable, stylish pockets by reinforcing key stress points with bartacks, using strong lining materials, and offering fully customizable stitching1, shapes, and placement to match your exact design specifications.

Pockets are more than just a place to hold a phone. For a designer like you, they are a signature.

The shape, the stitching, the placement—it all tells a story. I've seen brands build their entire identity around a unique back pocket design.

But none of that matters if the pocket rips after six months. Let's get into the details of how we build pockets that are as strong as they are stylish.

How do you reinforce pockets for durability?

A torn pocket corner or frayed lining makes your premium jeans look cheap. This single point of failure can undermine the customer's entire perception of your brand's quality.

We reinforce every pocket at its weakest points. We use bartack stitching2 at the corners and add hidden reinforcement patches3, ensuring the pocket can handle daily stress without tearing or failing.

In my 20 years of making jeans, I’ve learned that a pocket is only as strong as its weakest point. A designer's vision means nothing if the construction fails. That’s why we focus on two core areas for durability.

Reinforcing Stress Points

The corners of a pocket opening take the most abuse. We always add heavy bartack stitches here.

A bartack is a series of tight zigzag stitches that lock the corner in place and prevent the fabric from tearing.

For heavy-duty designs, we can also sew a small, hidden piece of reinforcing fabric (like a square or triangle patch) on the inside, right behind the pocket corner.

This distributes the stress over a larger area so a single point doesn't fail.

Stitching for Strength

We increase the stitch density at all high-stress areas to around 2-3mm per stitch. This tighter stitching increases the seam's tensile strength, making it much harder to pull apart.

The pocket opening itself is finished with a double process—an overlock stitch4 plus a flat seam—to stop the edge from fraying over time.

Can I choose between single or double-stitched pockets5?

You have a specific aesthetic in mind, but factory limitations force you into a generic look. Your signature pocket design ends up looking just like everyone else's.

Absolutely. We offer both single and double-needle stitching. You can choose the minimalist look of a single stitch or the classic, durable appearance of a double stitch to perfectly match your brand's style.

The type of stitching you choose for your back pocket is a key part of your design language. It is a detail that customers notice, and it communicates the style of the jean instantly.

We give you full control over this choice. You are not locked into one option. For a designer like you, this flexibility is crucial. Let's look at the two main options.

| Stitch Type | Visual Style | Best For... |

|---|---|---|

| Single-Stitch | Clean, minimalist, and modern. | Understated designs, contemporary fits, or when you want the fabric or wash to be the main focus. |

| Double-Stitch | Classic, rugged, and traditional. Creates a more three-dimensional look. | Heritage-inspired designs, workwear styles, or when you want to emphasize the pocket's shape and construction. |

A double-stitched pocket is inherently a bit more durable due to the parallel lines of thread, making it the standard for classic five-pocket jeans.

However, a single-stitched pocket, when combined with our other reinforcement techniques, is more than strong enough for premium denim. The choice is purely about your aesthetic vision.

What back-pocket shapes and placements are available?

Getting the back pocket "just right" feels impossible. The wrong shape or placement can make the jeans look unflattering, completely ruining the fit you worked so hard to perfect.

We offer complete customization. You can choose from standard shapes like classic arcuate or trapezoid, or provide your own custom logo shape6. We then adjust the size, angle, and placement for the perfect fit.

The back pocket is your brand's signature on the seat of the pants. It’s arguably the most important design element. I’ve helped designers tweak the placement by millimeters to get it perfect.

Pocket Shape Options

You are not limited to a standard "house" shape. We can create traditional straight or curved pockets, classic trapezoids, or even asymmetrical and custom shapes based on your brand's logo or a unique design sketch. Your creativity is the only limit here.

Precision Placement

Standard placement is symmetrical, with the top of the pocket sitting about 8 to 12 centimeters below the bottom of the yoke.

But "standard" is just a starting point. For a slim-fit jean, we might bring the pockets slightly closer together and place them higher to create a lifting effect.

For a relaxed or anti-fit style, we might drop them lower and space them wider apart. We work with your patterns to ensure the pocket placement complements the overall silhouette you designed.

How is the pocket lining material selected and installed?

You designed a beautiful jean, but the pocket lining is an afterthought. It is rough, it tears easily, or the color bleeds, making your premium product feel cheap.

We select lining based on durability and feel, often using a soft but strong cotton/poly blend7. The material is always pre-shrunk and properly installed with finished edges to prevent fraying and ensure comfort.

The inside of a jean is just as important as the outside, especially for a high-end product. The pocket lining, or "pocketing," is something the customer touches every day. A rough or flimsy lining sends the wrong message.

Selecting the Right Lining

We typically recommend a high-quality cotton-polyester blend (like 65% cotton, 35% polyester) between 80-120 g/m².

This blend offers the perfect balance: the cotton provides softness and breathability, while the polyester adds strength and abrasion resistance.

For dark raw denim, we always use a light-colored lining to prevent any indigo dye from bleeding onto the customer's hands or belongings. For workwear styles, we can use a heavier-weight twill or canvas for extra durability.

Professional Installation

We first cut the lining and finish all the raw edges with an overlock stitch. This prevents the material from fraying and falling apart inside the pocket.

The lining is then precisely aligned with the pocket bag and securely flat-seamed into place. We make sure to leave a tiny bit of slack, or "ease," in the lining so that when a customer puts their hand in the pocket, it doesn't pull or feel tight.

Conclusion

From reinforced corners8 to custom shapes and durable linings, we build pockets that perfectly match your design vision. They are guaranteed to last the lifetime of the jeans.

-

Find out how customizable stitching can elevate your jeans design and brand identity. ↩

-

Discover the significance of bartack stitching in enhancing pocket durability and style. ↩

-

Learn how hidden patches can significantly enhance the strength of your jeans pockets. ↩

-

Discover the benefits of overlock stitching in preventing fraying and enhancing durability. ↩

-

Learn about the pros and cons of each stitching type to make an informed choice for your designs. ↩

-

Find out how to incorporate your brand's logo into pocket design for a unique touch. ↩

-

Explore the ideal cotton/poly blend for pocket linings to achieve both comfort and durability. ↩

-

Learn about the importance of reinforced corners in ensuring the longevity of jeans pockets. ↩