Physical sampling is slow and expensive. The weeks spent shipping packages back and forth can kill your launch schedule and eat into your budget, creating endless frustration.

Modern factories use 3D virtual sampling1 to bring your designs to life in days, not weeks. We create an accurate digital twin of your jeans, allowing you to approve the fit, fabric, and wash before we ever cut a single piece of cloth.

For nearly 20 years, the process was always the same: we'd make a sample, ship it, and then wait weeks for the FedEx box to come back with feedback.

It was a slow, expensive dance. Today, technology has completely changed the game.

Virtual sampling allows us to collaborate with designers in a way I never thought possible. It bridges the distance between New York and my factory in Dongguan instantly.

It is not just about saving time and money; it is about making the creative process more fluid and precise. Let's break down how this technology works in the real world.

Can I See My Jean Design in 3D Before You Make It?

2D sketches are flat. They do not truly show how the fabric will drape or how the finished jeans will look, leaving you to guess and hope the sample turns out right.

Yes, we create photo-realistic 3D renderings2 of your designs. Just send us your tech pack or reference images, and we will build a digital model you can review from every angle.

Seeing your idea come to life in 3D is the first major step in replacing guesswork with certainty.

The process is simple. You provide us with your standard design documents—a tech pack with measurements, sketches, or even just some clear reference photos.

Our digital pattern makers3 then use this information to construct a detailed 3D model from the ground up. This is not just a simple drawing; it is a full digital prototype.

It includes the exact silhouette you designed, whether it is a slim, straight, or wide-leg fit.

We model every detail, from the style of the pockets to the placement of each rivet and button. Once it is built, we can send you high-resolution images of the model from any angle.

For a more immersive experience, we can even send you an interactive 3D link4 that allows you to rotate and inspect the design on your own screen. This usually takes just 1-3 business days.

How Accurate Are Virtual Fit Simulations?

You have to be sure the jeans will fit your customers. A bad fit can ruin an entire collection, and fixing it with endless physical samples is a slow and expensive nightmare.

Our virtual fit simulations5 are 85-95% consistent with physical samples for standard styles. We build them using 3D body scan data6 from your target market and input the exact properties of your chosen denim.

The accuracy of a virtual fit simulation depends entirely on the quality of the data behind it. It is much more than just putting a drawing on a digital mannequin.

First, we use virtual avatars built from thousands of real 3D body scans of consumers in your target market, whether it is the US or Europe. This ensures we are fitting the jeans to a body shape that represents your actual customer.

Second, and this is critical for denim, we input the specific digital parameters of the fabric you have selected. This includes its weight, its drape, and most importantly, its exact stretch and elasticity properties.

This is how the simulation can accurately predict how the jeans will hug the body. For standard fits, the results are incredibly reliable.

While it cannot replicate the feeling of soft, washed-down denim, it nails the structural fit—the measurements, the balance, and the silhouette—before we commit to a physical sample.

| Aspect of Fit | Virtual Accuracy | How It's Achieved |

|---|---|---|

| Structural Fit (Measurements) | 85-95% Accurate | Market-specific 3D body scans & real fabric data. |

| Silhouette & Drape | Very Accurate | Physics-based simulation of fabric weight and drape. |

| Tactile Comfort & Feel | Not Applicable | Requires a final physical sample for confirmation. |

Can I Tweak Textures and Washes Digitally?

Getting the wash perfect is the soul of denim design. But trying to explain the exact fade you want is difficult, often leading to samples that miss the mark completely.

Yes, our virtual system lets you see and adjust denim textures and wash effects7 visually. You can preview everything from a raw denim look to a heavy vintage wash and request changes instantly.

This is where virtual sampling becomes a powerful creative tool. It goes beyond just fit and pattern.

You can art direct the finish of your jeans right on the 3D model. Imagine you are working on a new design. You can ask us to show it to you with the texture of a heavy 16oz raw slub denim.

Then, with a few clicks, we can show you that same model with a lighter 10oz crosshatch fabric. The real magic is in the wash. As a washing expert, this is the part I love.

We have created a digital library of our most popular wash techniques. We can apply a realistic stone wash, a high-contrast acid wash, or a subtle, faded vintage effect to your 3D model.

You can then give precise feedback like, "Make the fading on the thighs a little lighter," and we can send you an updated rendering within a day. This visual collaboration removes all the ambiguity from the process.

How Do You Integrate My Virtual Feedback Into Production?

You have approved a beautiful 3D model. But you are worried that your detailed digital notes will get lost in translation when the design hits the real factory floor.

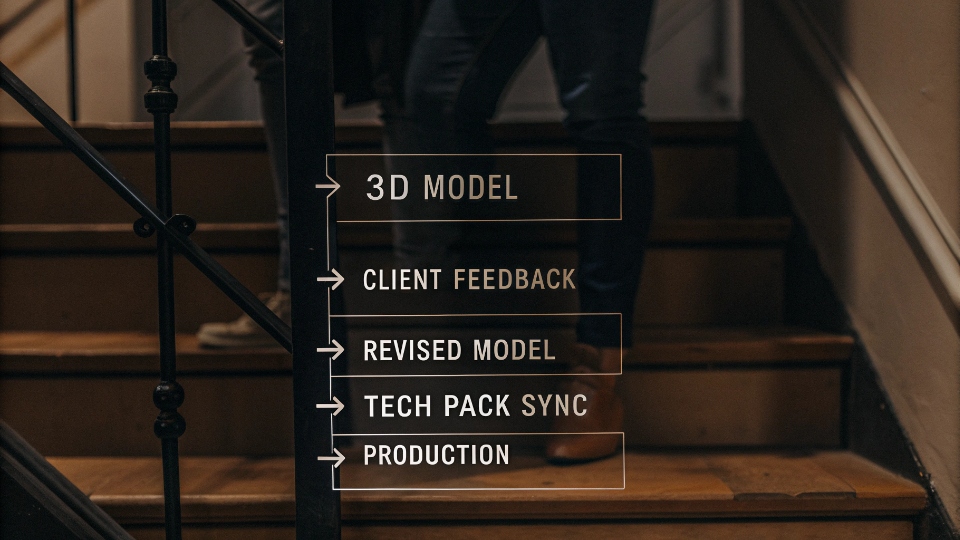

We have a standardized workflow that directly links your virtual approvals8 to our production tech packs9. The final approved 3D model becomes the official blueprint that our entire production team follows.

A digital design is useless if it cannot be perfectly replicated in the real world. We have built a process to ensure nothing gets lost.

First, you provide your feedback by marking up the 3D renderings or sending clear written comments.

Things like, "Increase the back rise by 1cm," or, "Use gold thread for the stitching."

We then make these changes in the 3D model and send it back to you. We repeat this digital loop until you give your final approval.

This next step is the most important: we synchronize the data from the final, approved 3D model with the master production tech pack.

The new measurements, the updated wash instructions, and all other details become the new official standard.

This updated tech pack, along with the 3D renderings for visual reference, is what our cutting, sewing, and washhouse teams use. Your digital approval becomes the new truth for production.

Conclusion

Virtual sampling saves time and money. It makes the design process faster, more collaborative, and far more accurate, ensuring your final jeans perfectly match the vision you approved digitally.

-

Explore how 3D virtual sampling revolutionizes the fashion industry by speeding up the design process and reducing costs. ↩

-

Discover the technology behind photo-realistic 3D renderings and their impact on design accuracy and client satisfaction. ↩

-

Learn about the role of digital pattern makers in transforming designs into detailed 3D models for production. ↩

-

Find out how interactive 3D links enhance the design review process by allowing clients to engage with their models. ↩

-

Understand the mechanics of virtual fit simulations and their role in ensuring accurate garment fitting before production. ↩

-

Explore the significance of 3D body scan data in creating accurate virtual fit simulations tailored to customer needs. ↩

-

Discover how digital tools allow designers to tweak denim textures and washes, ensuring the final product meets expectations. ↩

-

Learn how virtual approvals streamline the design process and enhance collaboration between designers and clients. ↩

-

Learn about production tech packs and their critical role in ensuring accurate manufacturing based on approved designs. ↩