You have just shipped a new collection. A customer reports a flaw. Now you worry if the entire batch is defective, a potential disaster for your brand's reputation and finances.

A robust batch control system is the answer. Every production run gets a unique code that links it to all materials and processes, allowing for the precise identification and isolation of any issues before they become a catastrophe.

I learned the importance of this the hard way many years ago. We received a shipment of denim from a trusted mill, and it looked perfect.

We produced a 5,000-piece order. After washing, we noticed a tiny, almost invisible horizontal line appearing on about 10% of the jeans. It turned out that one single roll of denim in the shipment had a yarn defect1.

Because we didn't have a sophisticated batching system back then, we had to inspect every single pair of jeans by hand. It was a nightmare. That experience taught me a valuable lesson.

It's not enough to make great jeans; you have to be able to prove how you made them, step by step. For a designer like Dean, this isn't just about quality control; it's about protecting his entire investment.

Can Each Production Run Carry a Unique Batch Code?

You worry that your products are just a number. Without unique identification, one issue in a single garment could cast doubt on the entire production order, costing you time and money.

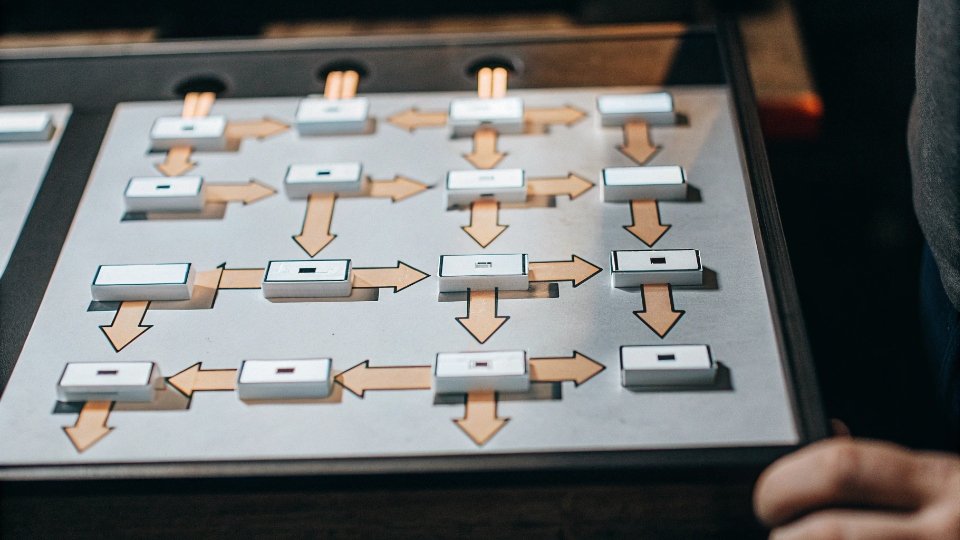

Yes, every single production lot we create is assigned a unique, intelligent batch code. This code is more than a random number; it is a key that unlocks the entire history of that specific batch.

Our system is designed for clarity and precision. The moment we plan a production run, we generate a unique batch code2.

This code is a structured piece of information, not just a sequential number. It tells a story. For example, a code might look like this: 240815-DNM701-L3-F45.

This translates to: Production Start Date (2024, August 15th), Style Number (DNM701), Production Line (Line 3), and Fabric Lot (F45). This structure ensures there are no duplicates and provides immediate context.

The code itself is physically and digitally married to the batch. It is sewn into the garment on an inner label, printed on the polybag, and marked on the master carton.

This physical marking ensures that even months later, on a retail shelf thousands of miles away, we can identify a garment's complete history with just that single code.

Anatomy of Our Batch Code

| Component | Example | Meaning |

|---|---|---|

| Date Code | 240815 | The date production started (YYMMDD). |

| Style Number | DNM701 | Your unique product identifier. |

| Production Line | L3 | The specific sewing line that assembled the garments. |

| Fabric Lot | F45 | The exact batch of denim fabric used from the mill. |

How Do I Trace Any Defects Back to Their Origin?

A customer finds a seam is unraveling. Is it the thread, the machine, or the operator? Without traceability, you are just guessing, unable to prevent it from happening again in the future.

The unique batch code is your starting point. We use it to pull up all the linked digital logs that trace the garment back through every step, from the specific roll of fabric to the operator who sewed the seam.

Imagine you report that a single pair of jeans from batch 240815-DNM701-L3-F45 has a stitching issue. Here is the exact path we can trace.

First, the -F45 code lets us pull up the inspection report for that specific fabric lot, including the supplier's name and delivery date. The -L3 code identifies the sewing line and the team leader responsible for that day.

Our internal logs for that line will show which operators worked on which station (e.g., inseam, pocket setting) and even which sewing machines were used. We can check the machine's maintenance log. We also trace the batch number for the thread used on that line that day.

This allows us to move from a broad problem—"a bad stitch"—to a highly specific root cause, such as "a bad spool of thread used by operator #27 on machine #12". This level of detail allows us to not only fix the problem but ensure it never happens again.

Are Wash Recipes Linked to Batch Numbers?

Your brand is known for a signature wash. If one batch comes out slightly off-color, you risk brand inconsistency and customer disappointment, but you have no idea why it happened.

Absolutely. Every wash load is treated as a sub-batch and is digitally linked to the main production batch number. Our system logs the exact wash recipe, chemical lot numbers3, machine settings, and timings for that specific group.

As a denim washing expert, this is an area where I am fanatical about control. The final wash is the soul of the jean, and consistency is everything. When a batch of jeans moves to our washhouse, the batch number is scanned.

This pulls up the approved wash recipe for that style. The washing machine operator then executes the recipe, and our system logs every critical variable.

We record which lot number of enzymes and softeners were used, the exact water temperature, the precise timing for each step (e.g., 25 minutes for the stone wash), and which machine was used.

If a batch ever looks even slightly different from the approved sample, I can use the batch number to pull up the complete wash log.

I can compare it to the log from the approved sample's batch and see if there was any deviation, no matter how small. This data-driven approach is how we guarantee a consistent wash, batch after batch.

What Digital Logs Support Full Traceability?

You need more than verbal promises of quality control. When an issue arises, or when customs asks for documentation, you need hard data and accessible records to make informed decisions.

We maintain a complete digital "paper trail" for every batch. This includes everything from the raw material inspection reports to the final QC checklists, all stored electronically and linked to the batch code for quick access and review.

Our commitment to traceability is backed by a robust digital record-keeping system. For every batch code, you can request a full traceability report. This is not just a summary; it is a compilation of all the original documents generated throughout the production process.

This digital file includes the fabric inspection4 report, the cutting records that show how patterns were laid out, the in-line and end-of-line sewing inspection5 records filled out by our QC team, the full wash log with all its parameters, and the final AQL inspection6 report before packing.

We retain these records for a minimum of seven years, ensuring you are covered for the entire lifecycle of your product.

We can provide this information to you through a secure online portal or as a complete PDF package, making it easy to satisfy retailer compliance requirements or pass third-party certifications7 like WRAP.

Conclusion

Batch control is your insurance policy. It protects your brand, ensures consistency, and provides complete accountability from raw fabric to the final garment, giving you total peace of mind.

-

Understanding yarn defects can help you prevent quality issues in your denim products. ↩

-

Learn how unique batch codes can help identify and isolate issues in production, ensuring quality control. ↩

-

Learn how chemical lot numbers are used to track and ensure the quality of washing agents. ↩

-

Understanding fabric inspection can help ensure the quality of materials used in production. ↩

-

Explore the role of sewing inspection in maintaining quality standards in garment production. ↩

-

Discover the significance of AQL inspection in ensuring product quality before shipment. ↩

-

Explore the importance of third-party certifications for ensuring product quality and safety. ↩