You've approved a beautiful final sample. But a single misunderstanding before production starts can lead to a container full of defective jeans, destroying your budget and your timeline.

The Pre-Production Meeting (PPM)1 is a final "lock-in" meeting before we cut bulk fabric. We align your approved sample with the tech pack, timeline, and quality standards, preventing costly errors by ensuring everyone is on the same page.

I remember a project with a new client. We had an approved sample for a jean with a very specific, custom-branded zipper. We had discussed it over email weeks before. But at the PPM, we were so focused on the wash and fit that nobody re-confirmed the zipper.

My production manager, trained to use our high-quality stock YKK zippers, started the run. We caught the mistake after the first 100 units were sewn.

We had to halt everything and wait two weeks for the custom zippers to arrive. That delay cost the client time and money. It taught me that the PPM isn't a formality. It is the single most important checkpoint to prevent errors.

What Key Topics Should We Cover Before Cutting Starts?

You're walking into the final meeting before production, but you are worried you'll forget a critical detail. One missed point could undermine the entire project, costing you thousands.

We focus on five non-negotiable pillars: the final approved sample, all tech pack details, the production timeline, quality control standards, and logistics. This covers your product from fabric to shipping container.

The goal of the PPM is to eliminate all assumptions. We do this by walking through a structured agenda that leaves no room for interpretation. We treat it like a pre-flight checklist for an airplane—every item must be confirmed before takeoff.

The most important artifact on the table is the "Golden Sample" or Pre-Production Sample (PPS). This is the physical version of the jean you approved. We literally sign and tag it during the meeting.

Then, we go line-by-line through your tech pack, holding it up against the Golden Sample to make sure they match perfectly. This is where we catch tiny but critical details.

Is the Pocketing material correct? Is the thread color exactly right? Is the placement of the back pocket embroidery precise? This intense final review is what separates a smooth production run from a disastrous one.

Our 5-Point PPM Checklist

| Category | Key Confirmation Points |

|---|---|

| 1. Product Specs | Signed Golden Sample, fabric, wash, thread, hardware, labels, size chart. |

| 2. Production Timeline | Dates for cutting, sewing, washing, finishing, and final inspection. |

| 3. Quality Control | QC checkpoints2, tolerance levels, and third-party inspection procedures. |

| 4. Logistics | Packaging details (polybags, hangtags), carton specs, and shipping marks. |

| 5. Compliance | Confirmation of standards like REACH or CPSIA3 for your target market. |

Can You Provide a Written PPM Summary?

The meeting felt productive, but you know that verbal agreements are easily forgotten. Without a written record, you risk disputes and errors down the line.

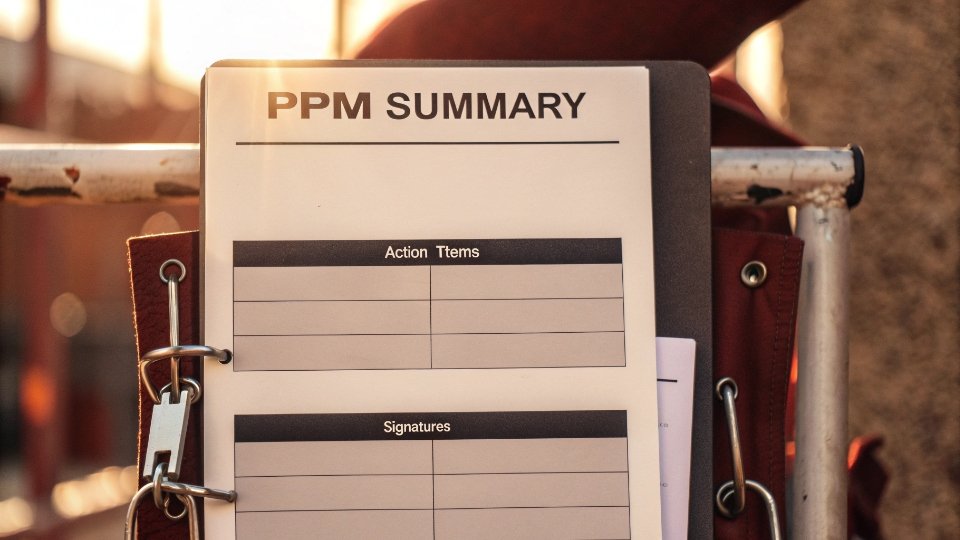

Yes. A verbal-only PPM is worthless. Within 24 hours of our meeting, we will send you a formal, written PPM summary4. This document is the final blueprint that we both sign before production begins.

The PPM summary is our contract of execution. It's not just a casual email with some notes; it is a formal document that becomes the single source of truth for the entire production run. My merchandiser is responsible for creating this report.

It methodically lists every single item we confirmed from our 5-point checklist. It will state, "Fabric confirmed as 12oz Candiani denim, color #45B." It will state, "Hardware confirmed as antique brass tack buttons, style Y-92."

It will also include a photo of the signed and dated Golden Sample. Any last-minute changes agreed upon during the meeting are highlighted in a special section. This document removes all ambiguity.

You read it, confirm it reflects everything we agreed on, and sign it. We sign it. Only then does my production manager get the green light to start cutting your order. This process protects both of us.

Who Attends From Their Team and Mine?

You want your vision perfectly executed, but you are not sure who needs to be in the room. You wonder if your presence is required, or if a junior team member can handle it.

The right people are essential. From our side, your Merchandiser, the Production Manager, and the QC Manager attend. From your side, the lead decision-maker on the product must be present, either in person or by video call.

A PPM fails if the decision-makers aren't there. It's pointless to have a meeting where the answer to every question is "I need to check with my boss."

This is why we insist on having the key leaders in the room (or on the screen). On my team, you will have the people who are directly responsible for making your jeans.

My Production Manager runs the entire factory floor. My QC Manager is responsible for ensuring every pair meets the standard we agree upon. And your Merchandiser is your project lead.

From your team, the person with the final say on the product—usually the lead designer like Dean or a senior Product Developer—is non-negotiable. Your technical designer is also highly valuable since they know the tech pack best.

In today's world, we run most of these meetings smoothly over video calls. This saves you the time and expense of travel without sacrificing any of the critical detail.

How Do You Track Our PPM Action Items?

You left the meeting feeling good, but you're worried about follow-through. How do you know that the agreed-upon changes will actually be implemented and not fall through the cracks?

Every action item from the PPM is captured in the written summary. We assign each item an owner and a deadline, and track it in a transparent system that you can view anytime.

Great meetings lead to clear actions. We have a simple but effective system for this. During the PPM, your merchandiser acts as the dedicated scribe.

In the final PPM summary document, there is a distinct section titled "Action Items." It doesn't just list what needs to be done; it specifies who is responsible and by when.

For example: "Action: Source alternative pocketing material. Owner: Merchandiser Jane. Due: October 25." Or "Action: Re-test fabric for shrinkage. Owner: QC Manager David. Due: October 24."

We then transfer this list to a shared project tracker, often a simple Google Sheet or Trello board. You get a link to this board. You can log in at any time and see the status of each item—Not Started, In Progress, or Completed.

This creates total transparency and accountability. It's my merchandiser's job to ensure every item is completed on time and to notify you as they are resolved.

Conclusion

A PPM isn't just another meeting. It's the foundation of trust and precision that ensures we build your vision correctly, turning your approved sample into a profitable, high-quality production run.

-

Understanding the PPM's role can help you avoid costly production errors and ensure alignment. ↩

-

Explore the importance of QC checkpoints to maintain product quality throughout production. ↩

-

Learn about CPSIA regulations to ensure your products meet safety standards. ↩

-

A detailed PPM summary is crucial for maintaining clarity and accountability in production. ↩