Your streetwear designs are fire, but generic factories can't execute them. You risk wasting money on bad samples. You need a specialist who understands the culture and the craft.

Find a custom streetwear manufacturer1 on B2B sites like Alibaba, but focus your search. Look for factories that specialize in streetwear by checking their past work. Always order samples2 to verify their quality, fit, and printing techniques before committing.

I've been in the denim game for over 20 years from my factory, DiZNEW, here in Dongguan. Streetwear is not just about a loose fit; it is an attitude. It requires specific washing techniques, heavy fabrics, and precise details that most factories just cannot handle. A good designer like my client Dean knows this.

He does not just need a sewer; he needs a technical partner3. Finding that partner is the most critical step. Let us break down how you can do it right.

How do I find a manufacturer for my clothing line?

It feels like a guessing game. You find a list of factories online, but you do not know who to trust with your brand and your money. You are looking for a reliable partner.

Start with a clear definition of your product needs. Use B2B platforms4 to create a shortlist, then vet them by ordering samples, checking their history, and asking for referrals. The best method is to confirm their capabilities yourself.

Finding the right factory is a process of careful elimination. You cannot just pick the first one with a low price. As someone who works with high-end brands, I know the level of detail they expect, and you should too. You need a systematic approach to find a partner who can deliver quality consistently.

A Step-by-Step Vetting Process

- Define Your Needs: Before you search, know exactly what you need. What fabrics? What printing or washing techniques? What is your target price and quantity? Have this clear so you can ask the right questions.

- The Online Search: Use platforms like Alibaba or Made-in-China.com, but be specific. Search for "streetwear hoodie manufacturer5" not just "hoodie manufacturer." Look at their company page. Do their product photos look like the style you want? Do they showcase experience with things like complex washes or detailed graphics?

- The First Contact: Reach out to 5-10 promising factories. Give them your design (a "tech pack" is best) and ask for a quote and their Minimum Order Quantity (MOQ)6. Pay attention to their communication. Are they clear, professional, and quick to respond?

- The Sample: This is the most important step. Never skip it. Order a sample from your top 2-3 choices. This is your chance to physically check their quality. Is the stitching clean? Does the fabric feel right? Is the fit correct?

- The Factory Visit: If possible, visit the factory. This is the ultimate test. At DiZNEW, we have built amazing, long-term partnerships with brands who came to visit us in Dongguan. It builds trust and ensures we both understand the quality standards7.

How do I start my own streetwear brand?

You have the ideas and the passion for streetwear culture8. But turning that into an actual business with products and sales seems complex and overwhelming. You have no idea where to even begin.

Start with a strong brand identity9 and a specific niche. Design a small, focused collection, find a specialized manufacturer for samples, build a community online, and then launch your product through an e--commerce store.

Starting a streetwear brand is as much about building a community as it is about making clothes. The product has to be excellent, but the story and the people behind it are what create a loyal following.

From my perspective as a manufacturer, the brands that succeed are the ones that are laser-focused from day one. They do not try to do everything at once. They follow a clear plan built on a few key pillars. Here's a simple breakdown of the process.

| Pillar | Key Actions | My Advice |

|---|---|---|

| 1. Brand & Niche | Define your brand name, logo, story, and your ideal customer. What makes you different? | Do not try to appeal to everyone. Be very specific. A brand for skaters is different from a brand for hip-hop fans. |

| 2. Design & Product | Create a small, cohesive first collection (e.g., 2 tees, 1 hoodie, 1 pair of jeans). Create professional tech packs for each. | Focus on your "hero" product. Make one item absolutely perfect. This is what you will be known for initially. |

| 3. Sourcing & Production | Find a manufacturer who specializes in streetwear. Order samples and build a relationship. | This is where we come in. A partner like DiZNEW, with strong development skills, can help refine your designs for manufacturing. |

| 4. Community & Marketing | Start building an audience on social media before you launch. Share your process, your brand story, and behind-the-scenes content. | Your first 100 customers will likely come from your community. Engage with them and build hype for your launch day. |

| 5. Launch & Logistics | Set up an e-commerce store10 (like Shopify). Plan your packaging, shipping, and customer service. | Make the customer experience great from the start. Good packaging can make your brand feel much more premium. |

How to find what manufacturer a brand uses?

You admire a brand's quality and want to use their factory. But this information is a closely guarded secret. It feels impossible to find out who makes their high-quality products.

It is very difficult, as this is confidential business information. You can check import/export data on sites like ImportYeti or look for clues on garment tags (RN numbers11), but there is no guaranteed method.

This is a question I get asked a lot. Brands see the quality of the jeans we make for our US clients and want to know who they are.

The truth is, these relationships are confidential. A brand's manufacturing partner is a key part of their competitive advantage. However, there are a few ways to do some research, though none are perfect.

The most common method for large public companies is to use import/export data12bases. Websites like ImportYeti or Panjiva track shipping records. You can search for a brand and see a list of their suppliers.

This works for huge brands, but it is often messy and does not work for smaller, private companies. Another clue can be the RN number on the garment's care tag in the US. You can look up this number online to find the company that imported the product, which can sometimes lead you to the source.

But let me give you a better piece of advice: instead of trying to find another brand's factory, find a factory that can replicate the quality you admire. A great manufacturer does not just copy.

They can analyze a garment and tell you how it was made, what fabric was used, and what washing process was applied. You can bring a sample to a factory like mine, and we can work with you to create your own unique product that meets or exceeds that quality standard.

How much does it cost to get clothing manufactured?

You need to create a budget but have no idea what things cost. Asking for quotes feels intimidating when you don't know the right questions or what is a fair price.

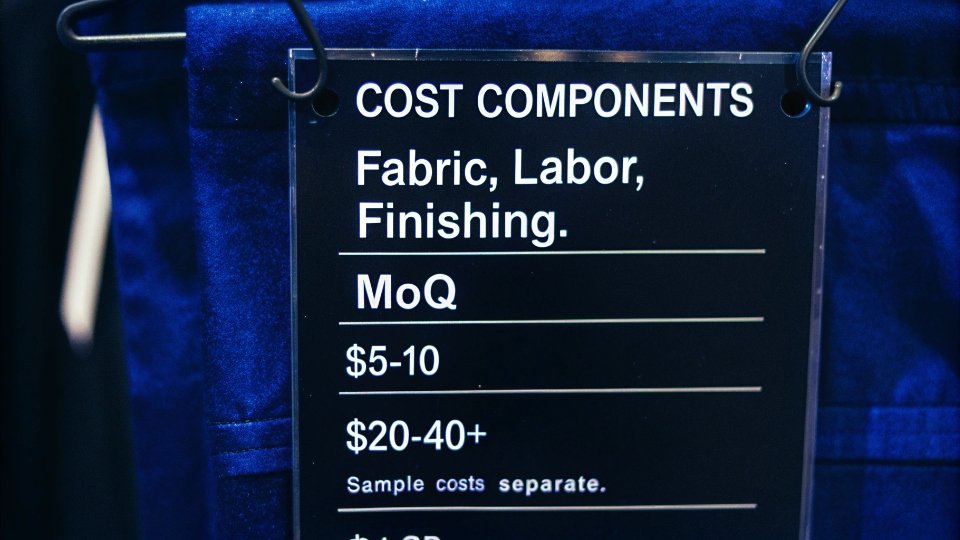

The cost per item depends on order quantity (MOQ), fabric, and complexity. A basic t-shirt might be $5-$10, while custom-washed streetwear jeans could be $20-$40+. Always factor in the cost of samples separately.

The final price of a garment is not one single number; it is built from many different factors. When a brand asks me for a quote, I need to know the details because every small choice affects the price.

Understanding these factors will help you design a product that fits your budget and will also help you understand the quotes you receive from factories. For streetwear, the details are everything, and they are also what drives the cost. Here are the main things that will determine your price.

The Key Factors That Determine Your Price

- Fabric: This is a huge part of the cost. A simple, lightweight cotton is cheap. A heavyweight, premium fleece or selvage denim for jeans is much more expensive.

- Construction Complexity: A simple t-shirt with two seams is fast and cheap to make. A hoodie with a lined hood, kangaroo pocket, special paneling, and ribbed cuffs requires much more labor and time, which increases the cost.

- Finishing & Details: This is especially important in streetwear. Do you need a custom garment dye? A multi-color screen print? Detailed embroidery? For jeans, a complex vintage wash with distressing can cost much more than a simple rinse.

- Quantity (MOQ): This is the biggest factor of all. A factory has setup costs for every new style. The cost per item for an order of 100 pieces will be much higher than the cost for 1,000 pieces because those setup costs are spread across more units.

Conclusion

Finding the right streetwear manufacturer is about partnership. Find a specialist, verify their skills with samples, and build a relationship to bring your unique vision to life with excellent quality.

-

Explore this link to find specialized manufacturers that can bring your unique streetwear designs to life. ↩

-

Understand the significance of ordering samples to ensure quality and fit before production. ↩

-

Find out how a technical partner can enhance your clothing production process and quality. ↩

-

Discover the best B2B platforms to connect with reliable manufacturers for your streetwear line. ↩

-

Learn how to locate manufacturers that specialize in streetwear hoodies for your brand. ↩

-

Learn about MOQ and how it affects your production costs and choices. ↩

-

Learn about the essential quality standards to look for when choosing a manufacturer. ↩

-

Delve into the elements that shape streetwear culture and its impact on design. ↩

-

Get insights on building a compelling brand identity that resonates with your target audience. ↩

-

Find the best e-commerce platforms to launch your streetwear brand online. ↩

-

Understand the significance of RN numbers in tracing garment manufacturers. ↩

-

Explore how to use import/export data to research potential manufacturers. ↩