Vague emails and language barriers create costly production errors. You need a partner who understands every detail, not someone who adds to the confusion.

A good factory assigns you a dedicated, English-fluent account manager as your single point of contact1. They use WeChat for fast updates2 and email for formal documents, ensuring nothing is lost in translation.

I've seen designers like you juggle contacts for production, quality, and shipping. It is a recipe for disaster.

Information gets lost, and everyone blames someone else. This is why the first and most critical part of a strong partnership is having one dedicated person on our side.

Their only job is to be your advocate and your voice within the factory. It simplifies everything and builds trust from day one. Communication shouldn't be your problem to solve; it should be our solution for you.

Who Will Be My Single Point of Contact?

You are tired of being passed from person to person when you have a simple question. This runaround is frustrating, wastes your time, and makes you feel like your project is not a priority.

You will be assigned one dedicated account manager3. This person is your single point of contact and is responsible for coordinating everything internally, so you never have to chase answers from different departments.

In my factory, your account manager is your project owner inside our walls. I built this system because I have seen the chaos that happens otherwise.

A designer might ask the production manager about a wash detail, who tells them to ask the wash technician, who is busy.

The information never gets back to you. Your single point of contact, or SPOC, eliminates this.

They know your project inside and out. If you have a question about shipping, they go to our logistics team and get you the answer.

If there is a quality concern, they work with the QC manager to resolve it. Their entire job is to own the communication flow4, giving you one person to talk to and holding us accountable.

This simple structure prevents miscommunication and ensures a smooth, efficient process from start to finish.

| Your Role | Your SPOC's Role |

|---|---|

| Ask questions about any topic. | Finds the right person internally. |

| Provide feedback on samples. | Translates feedback into technical instructions. |

| Request project updates5. | Gathers all information and provides one clear report. |

| Flag urgent issues. | Coordinates an internal emergency response. |

Will My Account Manager Actually Be Fluent in English?

You are worried your contact will have "business English" that sounds okay but misses crucial technical details. This small misunderstanding can lead to a sample that is almost right, but ultimately wrong.

Yes. Our account managers are not just fluent in conversational English; they are proficient in the technical language of denim6. They can accurately discuss fabric weights, wash processes, and construction details.

Over my 20 years in this business, I have seen millions of dollars wasted because of a single misunderstood word.

Someone might say they understand "stone wash," but do they know the difference between a 15-minute wash and a 45-minute wash? This is why I only hire account managers with deep industry experience who are truly bilingual.

They are not just translators. They are denim professionals who happen to speak excellent English.

They understand the nuances of your requests, ensuring that your creative vision is executed exactly as you intended. There is no room for "almost" in their vocabulary.

Their fluency covers all critical areas:

- Fabric Specifications: Describing slub, crosshatch, ounce weights, and stretch percentages.

- Washing & Finishing: Discussing enzyme washes, acid washes, laser patterns, and whisker placement.

- Garment Construction7: Clarifying stitch types, threads per inch, and pocket construction.

- Compliance & Testing8: Understanding international standards for materials and safety.

What Communication Tools Will We Actually Use?

Important project details get lost when using the wrong tool. An urgent question buried in an email causes delays, while a formal approval sent over chat creates confusion and lacks a paper trail.

We primarily use two tools: WeChat for instant messaging, quick photos, and real-time updates, and email for all formal communication like quotes, contracts, and final approvals.

In China, WeChat is more than a messaging app; it is an essential business tool. When your sample comes out of the wash, your account manager can instantly send you a video directly from the factory floor.

You can give immediate feedback. This closes the distance and dramatically speeds up the development cycle.

However, for anything that needs to be officially recorded, we always use email. This creates a permanent, searchable record that protects both of us. It is our official system of record.

We have found that Skype is often unreliable here and is not a standard tool for our teams. We stick to the combination of tools that provides the best of both worlds: speed and security.

| Tool | Best For | Example |

|---|---|---|

| WeChat/WhatsApp | Instant, informal updates and quick questions. | Sending a photo of a wash sample for fast feedback. |

| Formal documents, approvals, and official records. | Sending a final quote or a shipping notice. |

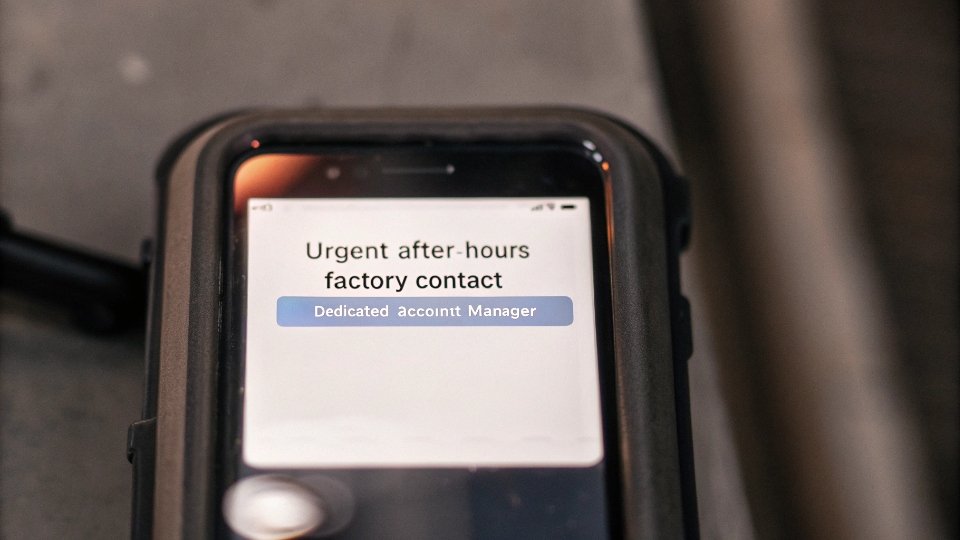

What Happens If I Have an Urgent Issue After Hours?

An urgent problem comes up, but it is the middle of the night in China. Your entire project is stalled, and you have to wait 12 hours just to get a response, creating massive anxiety.

Your dedicated account manager keeps their WeChat or WhatsApp accessible for urgent matters. For true emergencies, they can activate an internal response team and typically get back to you within a few hours.

The 12-hour time difference can be a major source of stress. We have a clear process to manage this. It is not about expecting someone to work 24/7. It is about having a system for emergencies. Here is how it works:

-

You Send the Message: You send an urgent message to your account manager's WeChat or WhatsApp, explaining the issue.

-

They Assess and Act: Your manager receives the notification and assesses the urgency.

-

Internal Activation: For a true emergency, they use our internal factory chat groups to contact the on-duty supervisor or relevant department head immediately, putting a hold on production if needed.

-

You Get a Response: They reply to you with confirmation that the message was received and an initial action plan.

For example, if you realize a fabric spec is wrong right before cutting is scheduled, your late-night message can stop a multi-thousand-dollar mistake.

This after-hours access is a safety net that protects your investment and gives you peace of mind.

Conclusion

With a dedicated English-fluent manager, the right tools, and clear processes, we eliminate communication barriers. This turns a supplier relationship into a true partnership you can trust from anywhere.

-

Learn why having a single point of contact can simplify project management and improve efficiency. ↩

-

Discover the benefits of using WeChat for instant updates and effective communication in business. ↩

-

Explore how a dedicated account manager can streamline your production process and enhance communication. ↩

-

Understand the importance of communication flow in ensuring project success and avoiding misunderstandings. ↩

-

Understand the role of regular project updates in fostering collaboration and keeping everyone informed. ↩

-

Delve into the specific terminology used in denim production to enhance your understanding and communication. ↩

-

Discover the critical aspects of garment construction that influence the quality and durability of clothing. ↩

-

Understand the compliance and testing standards necessary for ensuring quality and safety in denim production. ↩