Struggling to budget for your new denim line? Unclear manufacturing costs can be a major roadblock. I will break down the real costs involved in making a great pair of jeans.

The final factory price for a pair of jeans can range from $12 to over $60. This cost depends heavily on fabric choice, order quantity, design complexity, and the specific washing and finishing techniques used. A reliable manufacturing partner will provide a transparent cost breakdown for you.

Finding the true cost isn't about a single number. It's about understanding all the different pieces that add up to the final price. If you don't know what goes into it, you can't control your budget or your quality. Let's look at each of these pieces one by one. I want to give you the clarity you need to work with a factory confidently. When you understand the process, you can make better decisions for your brand.

Is denim expensive to produce?

Worried that your base material is eating up your budget? The cost of denim is a valid concern for every designer. I'll explain the factors that determine its price.

Denim fabric itself can cost anywhere from $3 to over $10 per yard. The final price depends on the quality of the cotton, the type of weave like selvedge, the fabric's weight, and any special finishes applied before it even reaches the cutting table.

The fabric is the soul of your jeans, and its cost is the first major variable. Not all denim is created equal. Over my 20 years in this business, I've seen how small differences in the raw material lead to big differences in the final garment. It starts with the cotton itself. Where it's grown matters. Then you have the weave. A standard twill is efficient to produce, but a premium selvedge denim, woven on old-style shuttle looms, is slower to make and costs more. The weight also plays a part; heavier denim uses more cotton yarn. Finally, think about the initial finishes, like sanforization to prevent shrinking. Each step adds to the per-yard cost.

Key Denim Cost Factors

| Factor | Lower Cost Option | Higher Cost Option | Why it Matters |

|---|---|---|---|

| Cotton Source | Standard Cotton Blends | Premium U.S. or Organic Cotton | Quality, feel, and durability |

| Weave | Standard Open-End Denim | Selvedge or Ring-Spun Denim1 | Texture, aging characteristics, premium feel |

| Weight | Lightweight (Under 12oz) | Heavyweight (14oz+) | Durability and structure |

| Dyeing | Standard Indigo Dye | Natural or Deep Indigo Dyeing | Color depth and fading potential |

How expensive is it to manufacture jeans?

You have your fabric, but what about the actual making? Hidden fees for labor and finishing touches can surprise you. Let's look at the complete picture of production costs.

The manufacturing cost, often called "Cut, Make, Trim" or CMT, can range from $8 for a simple jean in large quantities to over $50 for a complex design. This price is set by order size, design difficulty, washing processes, and labor rates.

This is where your vision truly comes to life, and it's also where costs can add up. The first step is often a sample. For a standard pair of jeans, a good sample from a quality Chinese manufacturer might cost you between $30 and $50. If your design is very complex with special details, that sample cost could rise to $80 or more. Remember, sample costs2 are high because we are only making one piece. There are no economies of scale.

Once you move to bulk production, the price per piece comes down significantly. The CMT cost3 covers everything after the fabric arrives. This includes cutting the patterns, sewing the pieces together, and adding the "trims"—the buttons, rivets, zippers, and patches. A simple five-pocket jean is straightforward.

But if you add complex decorative stitching, extra pockets, or unique paneling, the time and skill required increase, and so does the cost. Your choice of factory location also matters. I built DiZNEW in Guangzhou's Xintang district because it's known as the denim capital of the world, with access to skilled labor and top-tier facilities.

How much material does it take to make a pair of jeans?

Calculating fabric needs incorrectly leads to costly waste or production-halting shortages. It's a common mistake. Here is a simple guide for how much you really need.

A standard pair of straight-leg men's jeans typically requires about 1.5 yards of 58-inch wide denim. For larger sizes, flared cuts, or if the fabric pattern has a direction, you should budget for up to 2 yards per pair to be safe.

Estimating your fabric consumption, or "yield," is a critical step. A good factory partner will help you with this. We use a process called "marker making," where we arrange all the digital pattern pieces onto a layout of the fabric's width. The goal is to fit them together as tightly as possible, like a puzzle, to minimize waste.

Standard denim fabric comes in a width of about 58-60 inches, which is quite efficient. However, if you choose a premium selvedge denim, its width is only about 30-32 inches. This means you need almost double the yardage to cut the same pattern pieces.

I remember a client who insisted on buying his own fabric. He calculated 1.5 yards per pair for a complex design with large back pockets. He didn't account for the fabric's directional pattern. We ended up running short halfway through the cutting process, causing a two-week delay and extra shipping costs to get more fabric.

This is why accurate yield calculation is so important. Your style's complexity and the range of sizes in your order will also impact the final yardage.

How much does it cost to make jeans longer?

A standard size chart doesn't fit every customer body. You might think offering custom lengths is complex and expensive. But it doesn't have to be a major cost.

Adding length options during a production run adds very little to the cost, often less than $1-$2 per pair. This is because it only requires a minor digital pattern adjustment before cutting. In contrast, post-production tailoring is much more expensive.

Many brands miss a big opportunity here. Offering multiple inseam lengths4 can really set you apart and build customer loyalty. From a manufacturing standpoint, it's a very simple request. At my factory, we use digital pattern software for "grading," which is the process of creating all the different sizes from a base pattern.

Creating a 34x30, 34x32, and 34x34 size is as simple as adjusting the leg length in the software before we cut the fabric. The sewing and washing process remains exactly the same. The cost increase is minimal, mainly covering the extra bit of fabric used.

Trying to solve this problem after the jeans are made is the expensive way. Sending a finished pair of jeans to a tailor to be lengthened or shortened costs time and money, and it's hard to maintain quality control.

By planning for different lengths from the very beginning, you can offer your customers a better fit for a tiny fraction of the cost. It's a smart decision that shows you care about your customer's needs.

How much water to manufacture jeans?

The fashion industry's environmental impact is a huge concern. You might worry about your brand's water footprint. Let's look at the facts and the modern solutions available today.

A single pair of jeans can use thousands of gallons of water, from growing the cotton to dyeing and finishing. However, modern, sustainable factory techniques like ozone washing and laser finishing can reduce water use in the finishing stage by up to 90%.

The conversation about water usage is one I have with clients all the time. It’s important. The majority of the water is used at two key stages: growing the cotton and a distant second, the wet processing or "washing" stage. While we can't control the farm, we have immense control over what happens inside the factory.

This is where my passion for denim washing5 comes in. For decades, creating a "stonewashed" look meant tumbling jeans with actual pumice stones in huge amounts of water. To create faded or distressed areas, workers would sand them by hand, creating dust and using more water to clean them.

Today, we have amazing technology. At DiZNEW, we use lasers to create those same faded and distressed patterns with incredible precision and zero water. We use ozone gas machines to achieve a light, bleached look, which replaces long cycles in water-intensive washing machines.

These technologies not only save thousands of gallons of water per batch but also create a cleaner, safer work environment and often a more consistent, high-quality product. Choosing a factory that invests in these technologies is a powerful statement for your brand.

How to manufacture jeans?

The path from a sketch to a finished garment can seem overwhelming and complex. Where do you even begin the journey? I will outline the essential steps for you.

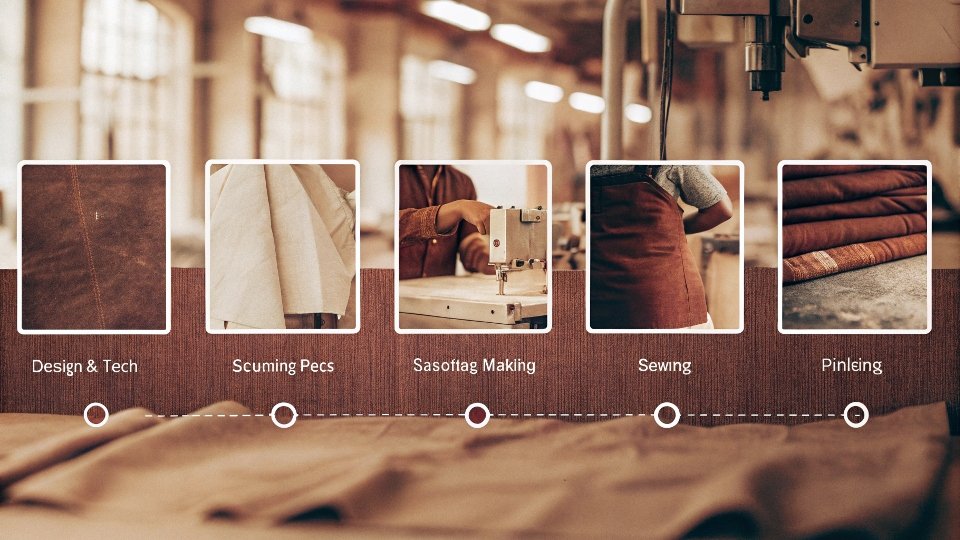

The jeans manufacturing process has seven main stages: Design & Tech Pack, Sourcing, Pattern Making & Sampling, Cutting, Sewing, Washing & Finishing, and finally, Quality Control & Packing. A great factory acts as your partner, guiding you through each critical step.

I've guided hundreds of designers like you through this exact process. Think of it as a clear roadmap.

- Design & Tech Pack: This is your blueprint. Your tech pack is a detailed document with sketches, measurements, fabric type, trim details, and washing instructions. The more detailed it is, the more accurate your sample will be.

- Sourcing: We find the perfect denim, buttons, rivets, and labels based on your tech pack.

- Pattern & Sample: We create a digital pattern and then a physical sample. This is your first chance to see and feel the product. We'll adjust it until it's perfect. This is where a factory in a hub like Xintang shines, with quick access to every possible material.

- Cutting: Once the sample is approved, we create the marker and cut the fabric for your full production run.

- Sewing: Skilled operators assemble the cut pieces into jeans on specialized sewing lines.

- Washing & Finishing: This is where the magic happens. The raw, dark jeans are washed, distressed, and finished to achieve your desired look using techniques we discussed.

- Quality Control & Packing: Every pair is inspected for flaws. We check measurements, stitching, and finish before they are folded, tagged, and packed for shipment to you.

Conclusion

Jean manufacturing costs are complex, but understanding fabric, CMT, and washing gives you control. Ultimately, your choice of a knowledgeable and transparent factory partner is your most important decision.

-

Understanding marker making can help you optimize fabric usage and reduce waste in your projects. ↩

-

Understanding sample costs is crucial for budgeting in clothing production. Explore this link to get detailed insights on pricing. ↩

-

CMT costs are essential for understanding the overall expenses in clothing production. This resource will clarify what these costs entail. ↩

-

Explore how providing various inseam lengths can enhance customer satisfaction and loyalty, setting your brand apart. ↩

-

Explore the latest innovations in denim washing to understand how technology is transforming water usage and sustainability in the fashion industry. ↩