You want to start your brand on a budget, but "cheap" manufacturers often mean low quality. This fear of getting bad products and losing money can stop you from even starting.

To get affordable manufacturing, go directly to factories in production hubs like China or Vietnam. Use B2B sites1 to compare quotes, simplify your designs to cut costs, and increase your order volume for a better price per piece.

For the last twenty years, I have seen brands come to my factory, DiZNEW, looking for a good price. Everyone wants to be smart with their money. But there is a huge difference between being "cheap" and being "cost-effective." Cheap means cutting corners on thread, fabric, and workers' skills.

Cost-effective means having an efficient process, smart sourcing, and a direct relationship with the factory owner2. My goal is to help you find the second option. Let's look at how you can get a great price without sacrificing the quality that will make your brand successful.

How do I find a manufacturer for my clothing line?

You are searching online, but every website promises the lowest prices. It is impossible to know who is a real factory and who is a middleman that will add costs and cause delays.

Use B2B platforms like Alibaba to find direct-from-factory suppliers. Filter for verified suppliers in industrial hubs, get quotes from at least five of them, and always order a sample to check their quality firsthand.

The key to a good price is to remove as many middlemen as possible. You want to talk directly to the people making your clothes. This is the fastest way to lower costs and improve communication.

Online platforms have made this easier than ever, but you need a clear strategy to sort through the noise. This is not just about sending one email; it is a process to find a reliable partner who can meet your price point.

The Direct-Sourcing Process

- Be Specific in Your Search: Do not just search for "clothing manufacturer." Search for "Guangzhou t-shirt factory3" or "custom denim4 Dongguan5." This will help you find specialists in areas known for production.

- Use Platform Filters: On sites like Alibaba, look for "Verified Supplier" or "Trade Assurance." These sellers have been checked by the platform, which adds a layer of security.

- Get Multiple Quotes: Send your design (your "tech pack") to 5-10 factories and ask for a quote based on a few different quantities (e.g., 100, 300, 500 pieces). This will show you who is competitive.

- Order a Sample: I cannot say this enough. Never place a bulk order without seeing, touching, and testing a physical sample. The factory that gives you the best sample at a good price is your best bet.

How much does it cost to get clothing manufactured?

You need to build a budget, but factory prices seem like a big secret. You are afraid of investing your time and money only to find out the final cost is double what you expected.

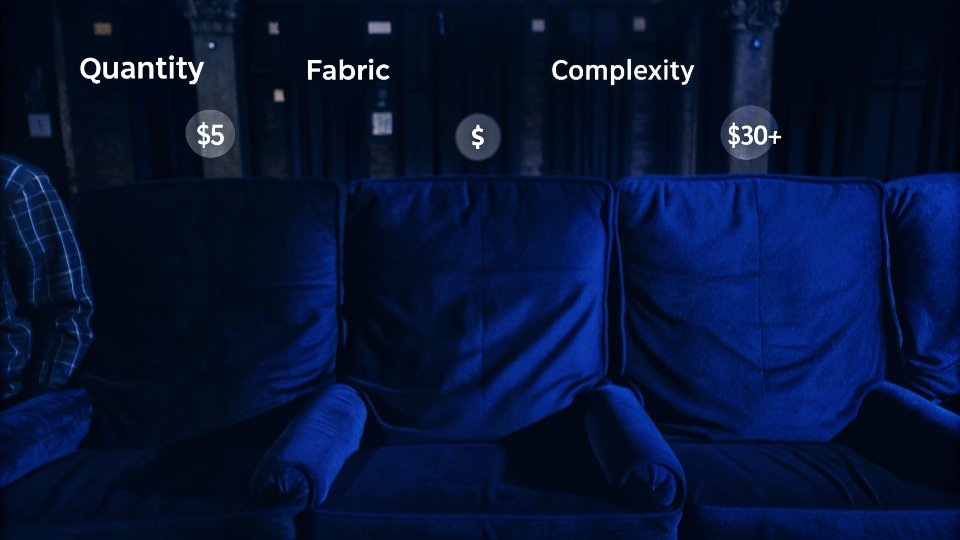

Manufacturing costs vary widely. A basic t-shirt might cost $5, while complex jacket could be $30+. The price depends on order quantity, fabric choice, and design complexity. Simplify these to lower your cost.

When a brand owner asks me for a price, I always ask for their tech pack first. The final cost of a garment is built from several key components. Understanding these parts will help you design a product that you can actually afford to produce.

If your first quote is too high, you can then adjust these elements to lower the price without ruining the quality. From a factory's point of view, these are the three main things that determine your cost per item.

| Cost Factor | How it Affects Price | How to Lower the Cost |

|---|---|---|

| Quantity (MOQ) | Smaller orders have a higher price per piece because setup costs are split among fewer items. | Place a larger order. This is the single most effective way to get a lower price. |

| Fabric | Custom or premium fabrics are expensive. | Use a standard, in-stock fabric that the factory regularly sources. |

| Complexity | More seams, pockets, zippers, prints, and special washes take more time and labor, increasing the cost. | Simplify your design. For example, choose a simple print instead of complex embroidery. Reduce the number of pockets. |

Some factories, like ours, can offer flexible solutions. At DiZNEW, we can support small batch orders6 starting from just 30 pieces to help new brands get started without a huge investment.

Where is it cheapest to manufacture clothes?

You hear that some countries are cheaper than others for manufacturing. You want the best price, but you are worried about quality, shipping times, and communication problems with a factory halfway across the world.

The lowest labor costs are often in Southeast Asia (Vietnam, Bangladesh). However, China offers the best balance of low cost, speed, supply chain maturity7, and skilled labor, especially in hubs like Guangzhou and Dongguan.

Many people automatically think of countries with the lowest wages as the "cheapest" place to make clothes. But the hourly wage is only one part of the final cost. As a factory owner in China, I can tell you that efficiency and supply chain are just as important. A factory might have cheap labor, but if they have to import all their fabric and zippers, you end up paying for it in time and money.

China has spent decades building the most complete apparel supply chain in the world. Here in Dongguan, the fabric mill is in the next town over. The button and rivet supplier is down the street.

The washing facility is part of my factory. This ecosystem means we can produce high-quality garments faster and often at a better total landed cost than other places.

China vs. Southeast Asia: A Quick Look

| Factor | China (e.g., Dongguan) | Southeast Asia (e.g., Vietnam) |

|---|---|---|

| Labor Cost | Moderate | Very Low |

| Worker Skill | High | Variable, often lower |

| Supply Chain | Excellent, everything is local | Developing, often relies on imported materials |

| Speed/Lead Time | Very Fast | Slower due to logistics |

| Infrastructure | World-class ports and logistics | Good, but can be less developed |

For brands that need a balance of good price, high quality, and speed, China is often the smartest choice.

How to find what manufacturer a brand uses?

You see a brand that has great quality and prices. You think, "I want to use their factory." But finding this information is nearly impossible because brands guard their supplier list carefully.

Finding a specific brand's factory is very difficult as it is confidential. You can check import data websites, but a better strategy is to find a factory that can replicate the quality you admire, not just the brand's name.

This is a common question. People want a shortcut to quality by finding out who makes clothes for a successful brand. The truth is, there is no magic list. These partnerships are private.

While you can try to dig through customs data on websites that track shipping containers, it is often inaccurate and only works for very large, public companies.

Instead of spending your time trying to find another brand's partner, I suggest a better approach. Spend your time finding a partner who can achieve the quality you are looking for. A good manufacturer is also a technical expert.

You can send us a garment from a brand you admire. We can analyze it. We can tell you what kind of fabric it is, how it was sewn, and what kind of washing process was used to finish it.

Then, we can work with you to create your own unique product that meets that same quality standard. This is how you build your own brand, not by copying someone else's supply chain.

Conclusion

Finding cheap manufacturers is about making smart, cost-effective choices. Go direct to the factory, simplify your designs, and build a partnership that values both price and quality for long-term growth.

-

This resource will guide you through the best B2B platforms to connect with reliable manufacturers. ↩

-

Learn why building a direct relationship with factory owners can lead to better pricing and quality. ↩

-

Find out about reputable t-shirt factories in Guangzhou that can meet your production needs. ↩

-

This resource will help you locate manufacturers specializing in custom denim production. ↩

-

Learn about the advantages of choosing Dongguan as a manufacturing hub for your clothing line. ↩

-

Discover the benefits of small batch orders for new brands looking to minimize risk. ↩

-

Explore how supply chain maturity impacts manufacturing efficiency and cost. ↩