You sketch beautiful jeans, but a lack of materials knowledge can cause production issues and poor quality. To bring your vision to life, you must understand what goes into a pair of jeans.

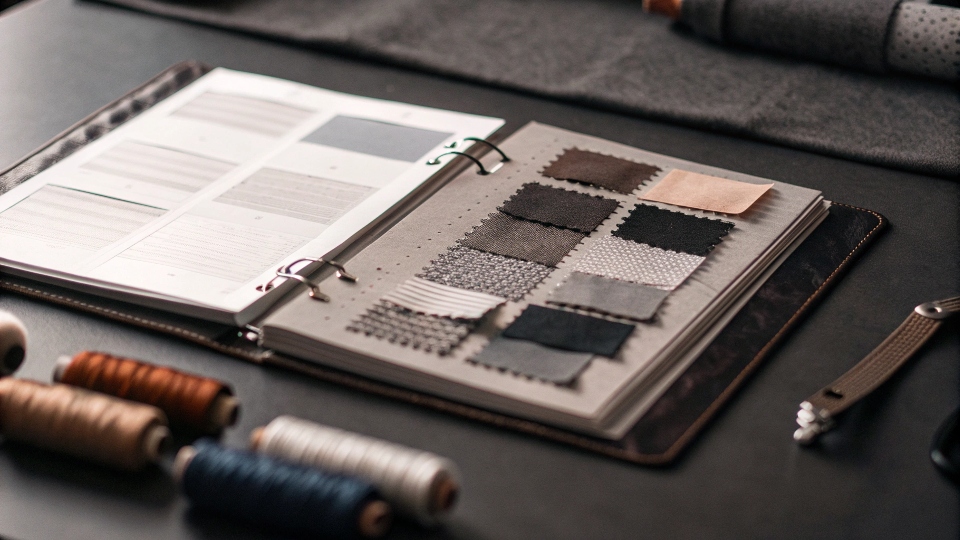

The main raw materials for jeans are cotton denim cloth for the body, metal rivets and strong thread1 for structure, and a zipper or buttons for function. Increasingly, sustainable materials2 like recycled cotton3 and eco-friendly dyes4 are becoming just as important.

After two decades in my denim factory, I've handled every single one of these components. I’ve seen how choosing the right cotton makes a jean feel luxurious and how the wrong rivet can fail.

It’s a system where every part matters. A great design on paper can only become a great product if you understand the building blocks. Let's break down exactly what those are.

What are the raw materials of denim jeans?

You see a finished pair of jeans, but it's hard to visualize all the individual parts. Not knowing them can lead to design flaws that compromise the final product.

The primary raw material is cotton denim fabric. This is supported by structural parts like metal rivets and buttons, strong thread, and functional items like zippers and labels. Modern jeans today almost always include stretch fibers like elastane for comfort.

I think of a pair of jeans in three main categories. First is the body, the fabric itself. Second are the parts that hold it together.

Third are the parts that make it functional and give it a brand identity. At my factory, we assemble these pieces for our clients every day, and the quality of each choice is critical. For a designer, knowing these categories helps organize your thoughts and your tech pack. It ensures you don't overlook a small detail that can have a big impact.

Here's how I break it down:

- Core Fabric Material: This is the heart of the jean. It's almost always cotton, which provides the classic feel and durability. High-quality jeans use long-staple cotton because the long fibers create a stronger, softer fabric. Cheaper jeans might use short-staple cotton, which can wear out faster. For stretch jeans, we blend in a small amount of elastane, usually around 2%. This provides comfort and movement but adding too much can make the jeans less durable over time.

- Structural Materials: These are the unsung heroes that keep jeans from falling apart. Strong thread, usually a cotton-polyester blend for extra strength, is used for all the seams. Metal rivets, made of copper or brass, are placed at stress points like pocket corners to prevent tearing. This was a genius innovation from the very beginning of jeans.

- Functional & Finishing Materials: This group of materials includes the zipper, typically a durable metal one from a trusted brand like YKK, and the main button at the waistband. It also includes all the labels, like the leather or paper patch on the back and the brand and care labels inside. Finally, it includes the indigo dye that gives jeans their iconic color, along with any chemicals or finishing agents used to create specific washes and distressed looks.

Why does it take 7500 litres of water to make a pair of jeans?

You hear shocking numbers about water usage in denim production5. This can make you question the sustainability of your designs and worry about your brand's environmental impact.

A huge amount of water is used mainly for growing the cotton crop, which is a very thirsty plant. Additional water is used in the yarn dyeing process and during the "finishing" or washing stages that give jeans their final look and feel.

This question about water is one I hear all the time, and it's a serious one. That 7,500-liter figure (about 2,000 gallons) is often cited, and while it can vary, it highlights a major challenge for our industry.

In my factory, reducing water consumption is one of our top priorities, and we've invested heavily in new technology to address it. Understanding where the water goes is the first step to finding solutions. The process has three main stages where water is heavily used.

- Growing the Cotton: This is the biggest factor by far. Cotton is a thirsty plant. It takes a massive amount of water to irrigate the fields to produce just one kilogram of cotton fiber. The good news is that there are better options emerging. Organic cotton often relies more on rainwater, and other fibers like hemp are being explored because they require significantly less water to grow.

- Dyeing the Yarn: The traditional process for dyeing yarn with indigo involves dipping it into multiple vats of dye and water. This creates the deep blue color we all know, but it uses and pollutes a lot of water. New technologies are changing this. We are now using foam-dyeing techniques6 that use almost no water, which is a revolutionary step forward.

- Finishing the Jeans: This is my area of expertise. To get that soft, "worn-in" look, jeans go through a series of industrial washes. Stone washing, enzyme treatments, and bleaching all traditionally use massive amounts of water. Today, we can achieve the exact same looks, or even better ones, using technologies like ozone gas and lasers. These processes use up to 90% less water and are much better for the environment.

What materials do you need to specify to make jeans?

You have a great design sketch, but turning it into a real product is overwhelming. You need a checklist of exactly what to tell your manufacturer to get the result you want.

To make a pair of jeans, you must specify the main denim fabric (weight, composition), the type and color of thread, all the metal hardware (rivets, buttons, zipper), and the complete label package. These choices will define the quality, cost, and final look.

When a designer like Dean sends me a tech pack, the more detailed it is, the better. Vague instructions lead to mistakes and delays. I always advise my clients to think of it as providing a complete recipe.

I can't bake the perfect cake if you just tell me "flour and sugar." I need to know amounts, types, and baking instructions. It's the same with jeans. A good tech pack should clearly specify every single material.

Here is a basic checklist I give to new designers to get them started:

| Material Category | Key Specifications to Include |

|---|---|

| Denim Fabric | 1. Weight: (e.g., 12 oz, 14.5 oz) 2. Composition: (e.g., 100% Cotton, 98% Cotton/2% Elastane) 3. Color/Dye: (e.g., Deep Indigo, Sulphur Black, PFD) |

| Stitching | 1. Thread Type: (e.g., Cotton-Poly Blend) 2. Thread Color(s): (e.g., Classic Gold, Tonal Navy) 3. Thread Thickness (Tex/Ticket): (e.g., Tex 80 for topstitching) |

| Hardware | 1. Buttons & Rivets: (e.g., Copper, Antique Brass finish) 2. Zipper: (e.g., YKK #5 Metal Zipper, Brass finish) |

| Labels & Patches | 1. Waistband Patch: (e.g., Genuine Leather, Jacron Paper) 2. Internal Labels: (e.g., Woven brand label, printed care label) |

This level of detail is a sign of a professional designer. It removes guesswork, ensures cost accuracy, and is the absolute best way to make sure the sample you get back from the factory looks exactly like the vision you had in your head.

Conclusion

Making jeans requires more than just fabric. It’s a combination of cotton, metal, and thread. Understanding these raw materials is the first step to creating a great, sustainable, and successful product.

-

Discover the importance of strong thread in ensuring the longevity of jeans. ↩

-

Find out how sustainable materials can improve the environmental impact of jeans. ↩

-

Understand the benefits of using recycled cotton in denim manufacturing. ↩

-

Explore how eco-friendly dyes contribute to sustainable fashion. ↩

-

Understand the environmental impact of water usage in jeans manufacturing. ↩

-

Learn how foam-dyeing techniques reduce water usage in denim production. ↩

[^5], a zipper, and spools of thread](https://diznewjeans.com/wp-content/uploads/2025/09/the-main-raw-materials-for-jeans-are-cotton-deni.jpg)