You’ve poured your heart into a new jeans design, but you're worried. A factory without the right legal permits could get your entire shipment seized, destroying your launch and your brand's reputation.

A jeans factory must have three core types of permits to operate legally: basic business licenses1, product safety certifications2 for chemicals, and environmental permits3 for the dyeing and washing processes. Without these, a factory cannot legally produce or export your goods.

For the past 20 years, I've managed my denim factory in Dongguan, China, and navigating this world of permits is part of my daily job. They aren't just pieces of paper to hang on the wall.

These licenses are a promise to you, my client, that your product will be made safely, ethically, and without the risk of being stopped at the border. Let me walk you through what really matters, so you can ask the right questions when choosing a manufacturing partner4.

What is licensing in the fashion industry?

You hear the term "licensing" and it sounds like a complex legal maze. You're concerned it's just another bureaucratic hurdle that stands between your creative vision and a finished product.

Licensing in fashion is simply official permission from a government or authority. It is proof that a factory meets the required legal standards for business operations, product safety, environmental protection, and worker safety. It’s the foundation of a reliable manufacturing business.

Think of it like this: you wouldn't hire a driver who doesn't have a driver's license. In the same way, you shouldn't partner with a factory that doesn't have the proper manufacturing licenses.

It's not one single permit, but a portfolio of certifications that cover different parts of the business. For a high-end designer like you, knowing your factory is fully compliant is critical for your brand's reputation.

These licenses prove that the factory is serious about quality, safety, and ethics. They show that we are not cutting corners and that we are committed to being a long-term, reliable partner. When you see our certifications, you know that we have been inspected, tested, and approved to meet international standards.

What is needed to make jeans?

Beyond the obvious things like fabric and sewing machines, you wonder what a factory really needs to operate professionally. You worry your partner might be missing a crucial element that could impact quality or delivery.

A professional jeans factory needs more than just materials. It requires a certified quality management system5 like ISO 90016, skilled and ethically treated workers, and all the necessary export licenses7 to legally ship your product around the world.

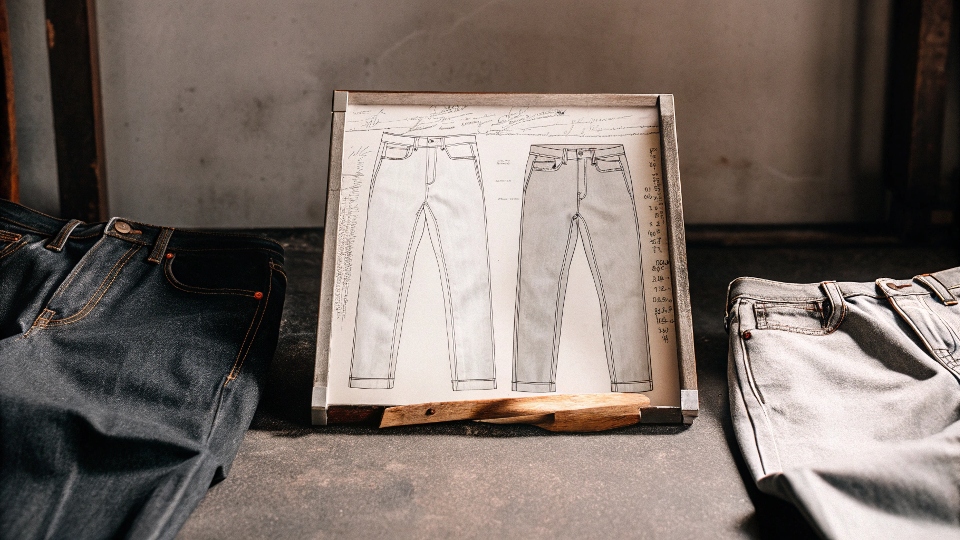

When clients come to my factory, I show them more than just our sewing machines and washing equipment. I show them our systems. Turning a design into thousands of identical, high-quality jeans requires a precise and certified process.

Here's what’s truly needed:

- Quality Management System (ISO 90016): This isn't a government law, but it's a certification that serious brands demand. It proves we have a documented, repeatable system for ensuring quality at every step, from checking raw materials to the final inspection. It's your peace of mind that the 1,000th pair of jeans will look just as good as the first sample.

- Export and Customs Licenses: This is absolutely critical. Our factory must be registered with Chinese customs to legally ship products to you in New York. We also handle documents like the Certificate of Origin8, which can help reduce the import taxes you pay. A factory without these licenses can't get your product out of the country.

- Workplace Safety & Ethical Certifications9: We need permits for fire safety and occupational health. This ensures our team is working in a safe environment. It's not only the right thing to do, but it also protects your brand from being associated with unsafe labor practices and prevents unexpected factory shutdowns that could delay your entire season.

What is the production process of jeans?

You understand the design process inside and out, but the factory floor is a black box. You're concerned that issues hidden within the production steps could compromise your final product's quality and safety.

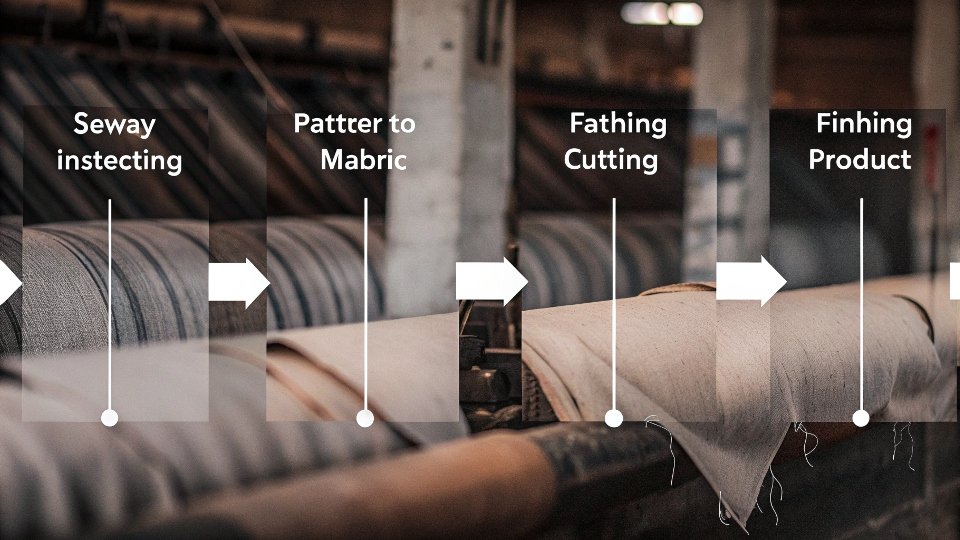

The production process flows from pattern making and cutting the fabric to sewing, washing for style and softness, and a final quality inspection. Each step is governed by different safety and quality rules, especially the washing stage, which requires strict environmental permits3.

Let me give you a quick tour of my factory floor and show you where these permits and licenses come into play at each stage. It's a journey from a simple roll of raw denim to the finished product you designed.

| Production Step | How Licenses and Permits Apply |

|---|---|

| 1. Pattern & Cutting | Our ISO 90016 quality system ensures every piece is cut precisely. Workplace safety permits make sure the cutting machines and area are safe for our team. |

| 2. Sewing | The skill of our workers is key here, and ethical labor standards ensure they are treated well. Our quality system dictates the stitch per inch and thread type to match your specs. |

| 3. Washing & Finishing | This is the most regulated step. We need an Environmental Impact Assessment (EIA)10 and a Pollutant Discharge Permit11 to operate our wash house. This proves our wastewater is treated before it leaves the factory. |

| 4. Final Inspection & Packing | Every pair is checked for compliance with product safety standards like REACH (EU)12 or CPSIA (US)13. This is a final check to ensure there are no harmful chemicals before we pack and ship. |

As you can see, the permits are not just for the government. They are integrated into the daily process to ensure everything is done correctly, safely, and to the highest standard. This systematic approach is the only way to guarantee a perfect product every time.

Is there a patent on jeans?

The design of a five-pocket jean is timeless and iconic. You might worry if the basic construction is protected by a patent, which could restrict your creative freedom as a designer.

No, the basic concept of jeans is not under patent. The original 1873 patent for using rivets on pants expired in 1890. While you are free to make five-pocket jeans14, specific creative elements like logos, stitch patterns, and unique hardware can be protected by trademarks15.

This is a great question, and it shows the difference between universal manufacturing and specific brand identity. The original patent filed by Jacob Davis and Levi Strauss was for the idea of using copper rivets to strengthen the stress points on work pants.

It was a revolutionary idea, but like all patents, it had an expiration date. Once it expired, anyone was free to use rivets on pants, and the entire denim industry was born.

So, you can absolutely create your own version of a classic five-pocket jean. However, you cannot copy the unique design elements that other brands have protected. For example:

- The famous arcuate stitching on the back pocket of Levi's jeans is a registered trademark. You cannot copy that specific shape.

- A unique button design or a special wash pattern can be protected by a design patent16.

- The brand's name and logo are also protected by trademarks15.

This is actually great news for you as a designer. It means you have a solid, proven foundation to build upon, but you can also protect your own unique creative ideas. Your original pocket designs, hardware choices, and branding can all become your own intellectual property17.

Conclusion

Choosing a factory is about more than cost. It's about finding a partner with the correct legal permits. This protects your brand, guarantees quality, and ensures your products are made ethically and delivered safely.

-

Understanding these licenses is crucial for ensuring your factory operates legally and avoids costly disruptions. ↩

-

These certifications ensure that your jeans meet safety standards, protecting your brand and customers. ↩

-

These permits are essential for sustainable practices and compliance with environmental regulations. ↩ ↩

-

Choosing the right partner ensures quality production and protects your brand's reputation. ↩

-

A certified system like ISO 9001 guarantees consistent quality, which is vital for your brand's reputation. ↩

-

ISO 9001 certification ensures that your factory maintains high-quality standards throughout production. ↩ ↩ ↩

-

Export licenses are critical for legally shipping your products internationally and avoiding legal issues. ↩

-

This document can help reduce import taxes, making your products more competitive in international markets. ↩

-

These certifications ensure safe working conditions and ethical labor practices, protecting your brand's image. ↩

-

An EIA is crucial for understanding the environmental effects of your production processes. ↩

-

This permit ensures that your factory complies with environmental regulations regarding wastewater. ↩

-

REACH compliance is essential for ensuring that your products are safe for consumers in the European market. ↩

-

CPSIA compliance is necessary for ensuring the safety of children's clothing in the U.S. market. ↩

-

Understanding patent laws can help you navigate design freedom and protect your unique creations. ↩

-

Trademarks protect your brand identity, ensuring that your unique designs and logos are legally safeguarded. ↩ ↩

-

A design patent can protect your unique design elements, giving you a competitive edge in the market. ↩

-

Understanding intellectual property rights is crucial for protecting your creative ideas and designs. ↩