You approved a perfect sample, but now you're worried. Will the 1,000 pairs in your bulk order have that same quality? A weak quality control process can turn your dream design into a nightmare.

A professional factory must apply a multi-stage quality control process1. This includes incoming fabric testing2 for shrinkage and colorfastness3, in-line inspections4 during sewing, wash consistency validation5, and a final AQL inspection before shipment.

Over my 20 years in the denim business, I've seen it all. The biggest failures happen when quality is treated as a final step instead of a process.

A single final inspection is too late; by then, the problems are already sewn into the fabric. At my factory, DiZNEW, we build quality into every stage. Think of it as a series of gates.

A product cannot pass to the next stage until it meets the standard at the current one. Let's walk through what this process should look like so you know exactly what to demand from any supplier.

How Do You Monitor Fabric Shrinkage and Colorfastness?

You approve jeans with the perfect fit, but after the first wash, customers complain they've shrunk.

Or the beautiful indigo dye bleeds onto everything, ruining a customer's white sofa and your brand's reputation.

We perform lab tests on every batch of fabric before it is cut. We test for shrinkage using the AATCC 135 standard6 and test for colorfastness against washing, rubbing, and light to guarantee stability.

Everything starts with the fabric. If the raw material is flawed, the final garment will be flawed.

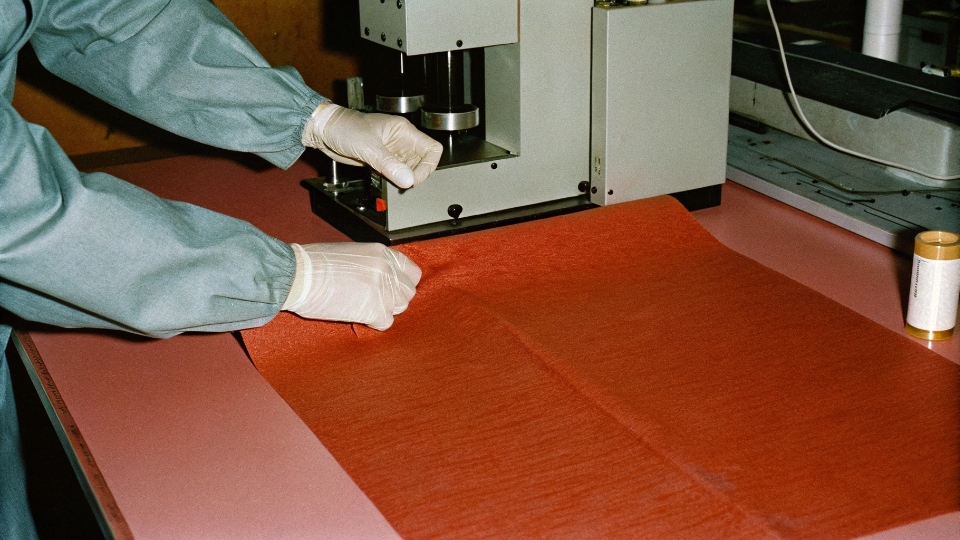

Period. That's why the first quality gate is our incoming fabric inspection. Before we even think about cutting, we take samples from each new roll of denim. First, we test for shrinkage.

We cut a template, wash it according to standard home laundering procedures (AATCC 135), and then re-measure it.

My rule is that shrinkage must be under 3%, or we reject the fabric. Next, we check colorfastness.

We run tests to make sure the color doesn't bleed when washed or rub off on other surfaces. We also test its resistance to fading from light.

Only after the fabric passes these certified tests do we approve it for production. This step is non-negotiable; it protects your fit and your customer's experience.

What In-line Inspections Occur During Cutting and Sewing?

A single cutting error or a misaligned sewing machine can create hundreds of defective garments7. If these mistakes are only caught at the end, it results in massive waste and huge delays for your order.

We inspect at every step. We check the first cut pieces against the pattern for accuracy. During sewing, dedicated inspectors roam the production line to check for skipped stitches, seam allowance, and correct pocket placement.

The goal of in-line inspection is to catch problems the moment they happen.

We start in the cutting room. After the first 10 to 20 pieces are cut, we stop and do a "first cut check." We lay the pieces directly on top of the master pattern to ensure perfect alignment and accuracy.

Once cutting is approved, the pieces move to the sewing lines. Here, we don't wait until a garment is finished.

We have quality inspectors assigned to each sewing line. They constantly move between stations, checking for common errors like skipped stitches, uneven seam widths, and crooked pockets.

We also perform specific checks on critical components. For example, we do a pull test on a sample of buttons and rivets to ensure they are secure.

We check every zipper to make sure it runs smoothly. This constant monitoring means we can correct a small issue before it is repeated on hundreds of pairs.

How Do You Validate Wash Consistency at Your In-house Facility?

Your sample has a beautiful, unique wash. But when the bulk order arrives, some pairs are too dark, some are too light, and the distressing is all over the place. This inconsistency makes your product look cheap.

We create a precise "wash recipe8" based on your approved sample. Before washing a full batch, we test-wash a small lot of 5-10 pairs and compare them side-by-side with the master sample to ensure a perfect match.

As a denim washing specialist, this is the part of the process I am most passionate about.

A great wash is art, but making it consistent requires science. Once you approve a wash sample, we document every single variable to create its official "wash recipe."

This includes the exact chemical formula, water temperature, wash duration, machine speed, and even the size and quantity of stones used.

But even with a recipe, we still verify. For every new production batch, we first pull 5 or 10 pairs and run them through the complete wash process.

Then, we take these test garments and compare them directly against your original approved sample under special color-matching lights. Only when we have a perfect match do we proceed with washing the entire batch.

After the wash, we do another check for any defects like pilling or broken threads. This ensures every pair has the exact signature look you designed.

Can I Request Third-party Lab Tests Before Shipment?

You receive a quality report9 from the factory, but you want an objective, unbiased confirmation. A supplier who resists outside inspection may have something to hide, leaving you to worry about what might really be in the box.

Absolutely. We welcome and encourage third-party testing. We will fully cooperate with any lab you choose, like SGS10 or Intertek, and provide them with access to the product for pre-shipment inspection and testing.

A confident factory should never be afraid of an outside expert.

In fact, we welcome it. Allowing a third-party inspection from a trusted company like SGS, Bureau Veritas, or Intertek is a sign of transparency and a commitment to quality.

You just need to tell us which lab you want to use and what specific tests you require.

Common requests include tests for restricted substances (like lead in buttons or certain chemicals in the dye), fabric composition verification11, and a final AQL inspection12.

We will help schedule their visit to our factory. Typically, the client covers the cost of the inspection.

However, if the inspection fails, we are responsible for fixing the issues and will often cover the cost of the re-inspection.

This provides you with a final, unbiased layer of security before the goods are shipped, giving you complete peace of mind.

Key Third-Party Inspection Points

| Area of Discussion | Your Key Question | A Good Supplier's Answer |

|---|---|---|

| Acceptance | "Do you allow third-party inspectors like SGS?" | "Yes, absolutely. We can help you coordinate." |

| Cost | "Who pays for the inspection and any re-tests?" | "You pay for the initial test. If it fails, we fix the issue and pay for the re-test." |

| Handling Failure | "What happens if the shipment fails inspection?" | "We will quarantine the goods, rework them to meet the standard, and schedule a re-test." |

Conclusion

A comprehensive, multi-stage quality control plan is not a luxury; it is a necessity. It is the only way to transform your design into a consistent, high-quality product that builds your brand.

-

Understanding the multi-stage quality control process can help ensure your products meet high standards. ↩

-

Learn about the importance of incoming fabric testing to prevent quality issues in your products. ↩

-

Discover how these tests protect your brand's reputation and customer satisfaction. ↩

-

Explore how in-line inspections can catch defects early, saving time and resources. ↩

-

Learn about the techniques used to ensure consistent wash results for your products. ↩

-

Familiarize yourself with this standard to ensure your fabric meets industry benchmarks. ↩

-

Understanding the causes of defects can help you improve your manufacturing processes. ↩

-

Discover how a precise wash recipe can maintain the quality and appearance of your jeans. ↩

-

Discover the key elements of a quality report to ensure transparency and trust. ↩

-

Explore the services offered by SGS to enhance your quality control processes. ↩

-

Learn about the importance of fabric composition verification for product quality. ↩

-

Understanding AQL inspections can help you ensure your products meet quality standards. ↩