You approved a sample with the perfect weight and stretch. But the bulk order arrives, and the fabric feels cheap and different. Now your inventory is inconsistent, and your brand's quality is at risk.

To guarantee a perfect match, your factory must provide third-party lab reports1 that verify fiber content2 and weight. They should also perform their own in-house checks on every single fabric roll before it is cut.

The fabric is the foundation of everything. In my 20 years of making jeans, I have learned that you can have the best design and the most skilled sewing operators, but if the fabric is wrong, the entire product fails.

A cheap fabric will not wash correctly, it will not fit correctly, and it will not last.

This is why a true manufacturing partner takes fabric sourcing3 and verification as seriously as you do.

We do not just trust the label on the roll; we test it. Because we know that the reputation of your brand is literally woven into every single thread.

How do they verify fiber content and weight specifications4?

You specified 12oz denim with 2% elastane. The factory says "no problem," but you have no proof. You worry that they will use a cheaper, lighter fabric to cut costs.

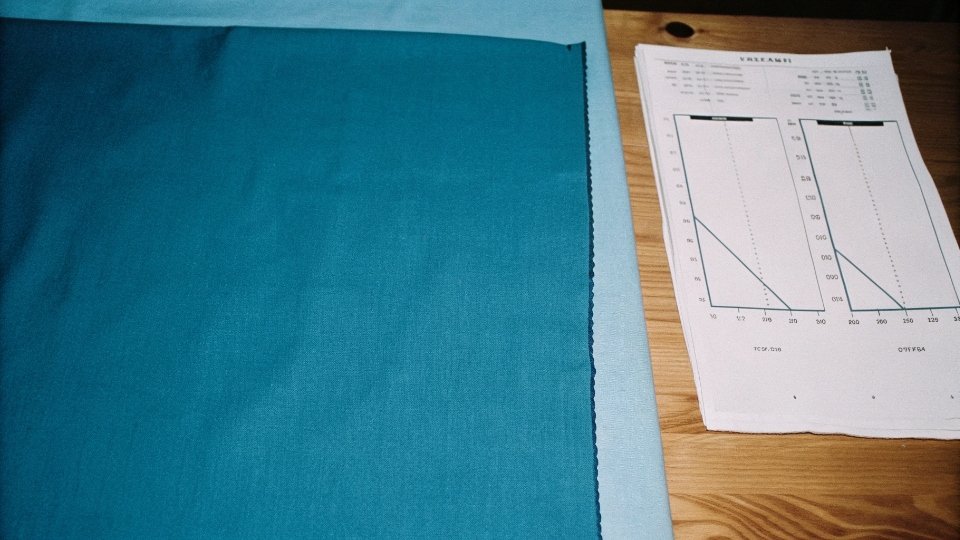

We verify fabric two ways. First, we send a cutting to an independent lab like SGS for a certified report. Second, we weigh and inspect every roll that enters our factory. If a roll does not match your spec sheet, we reject it immediately.

Trust, but verify. This is my motto when it comes to fabric. A mill can make a mistake, or a supplier might try to cut a corner. We protect you from this.

The first step is always getting a

third-party lab certificate. This is non-negotiable proof that the fiber content, like 98% cotton and 2% spandex, is exactly what you ordered.

But we do not stop there. When the rolls of fabric arrive at our factory, my team personally weighs swatches from each one. If your spec sheet says 12oz denim, and a roll comes in at 11oz, we do not use it.

We will notify you and reject the roll. This two-step verification process guarantees that the foundation of your jeans is perfect before we even think about cutting.

Can they source organic, recycled, or specialty denims5?

Your brand is built on sustainability and unique style. You need GOTS-certified organic cotton6 or a special selvedge denim, but you are not sure if a factory in China can find it.

Yes, we have a network of specialized mills that provide a wide range of certified sustainable and specialty fabrics. This includes GOTS organic cotton, recycled denim7 from post-consumer waste, and premium selvedge denim.

The world of denim is much bigger than just standard cotton.

Today, the fabric itself tells a story. Our clients come to us for these unique materials, and we have spent years building relationships with the best mills to provide them.

Whether you need the soft feel of a Tencel blend, the eco-friendly credentials of GOTS-certified organic cotton, or the authentic, old-school look of selvedge denim, we can source it for you.

We understand the importance of certifications. When you order an organic or recycled fabric, we do not just take the mill’s word for it.

We provide you with the certification documents8, like the GOTS transaction certificate, so you have a clear and traceable supply chain. This allows you to confidently tell your brand’s sustainability story to your customers.

What lead time applies for custom fabric orders9?

You have a tight production schedule. The factory gives you a vague timeline, but you do not know how long it takes to actually get the fabric, which can cause major delays.

A standard in-stock denim takes about 7-14 days to arrive. However, a custom-milled fabric, like a unique blend or a special weight, requires a lead time of 20-35 days from the mill. It is critical to factor this into your schedule from day one.

Fabric lead time is one of the most common reasons for production delays. A good plan starts with a realistic timeline. We break it down for you so there are no surprises.

If you choose a standard 12oz cotton-spandex denim that our partner mill keeps in stock, we can have it in our factory in about two weeks.

But if your design calls for something special, like a custom-developed 13oz blend of cotton and recycled polyester, the mill has to produce that specifically for you.

This process, from ordering the yarn to weaving and finishing the fabric, can take over a month.

We always confirm this lead time upfront and advise you to approve your fabric choice as early as possible. This ensures that the fabric is ready and waiting the moment your production slot opens up.

How do they ensure fabric uniformity10 between different lots?

Your first production run was perfect. But the re-order comes in, and the color is slightly different and the jeans fit a bit tighter. The factory used fabric from a new lot.

We ensure uniformity by ordering all fabric for your entire production run from a single mill lot11. If we must use a second lot, we will send you a sample from both lots for a side-by-side approval before we cut anything. This is a critical quality control step12.

This is a problem I have seen hurt many brands. Even fabric from the same mill can have slight variations in color or stretch from one production lot to the next.

The only way to guarantee absolute consistency across a 1,000-piece order is to make sure every pair is cut from the exact same batch of fabric.

We manage this by working closely with our mills to reserve a single, continuous lot for your entire order.

In situations where an order is so large that it requires more than one lot, we have a strict protocol. We will cut a swatch from the old lot and the new lot, sew them side-by-side, and send them to you.

You get to see and feel the difference, if any, and give us your final approval before we proceed. We never mix lots without your explicit permission. This guarantees the consistency your customers expect.

Conclusion

The right fabric is the non-negotiable foundation of a great pair of jeans. A truly professional partner will verify its content, source exactly what you need, and guarantee its consistency.

-

Explore how third-party lab reports ensure the quality and specifications of your fabric, protecting your brand's integrity. ↩

-

Learn about the importance of verifying fiber content to maintain the quality and durability of your products. ↩

-

Explore the critical role of fabric sourcing in maintaining your brand's quality and reputation. ↩

-

Understanding weight specifications is crucial for ensuring your fabric meets design and quality standards. ↩

-

Discover the unique characteristics of specialty denims and how they can enhance your product line. ↩

-

Find out why GOTS certification is essential for organic cotton and how it impacts sustainability. ↩

-

Understand the sourcing of recycled denim and its role in sustainable fashion. ↩

-

Learn about the necessary certification documents that ensure transparency in your fabric sourcing. ↩

-

Get insights into the lead times for custom fabric orders to better plan your production schedule. ↩

-

Learn about the processes that ensure fabric uniformity across different production lots for consistent quality. ↩

-

Understand the significance of mill lots in ensuring consistency and quality in fabric production. ↩

-

Explore the essential quality control steps that protect your brand from inconsistencies in fabric quality. ↩