Making sustainable jeans1 but worrying about hidden pollution is a huge brand risk. A factory's wastewater can destroy the environment, creating a major liability for your company's reputation.

We use a multi-stage wastewater treatment system2 to remove all harmful chemicals, recycle water for reuse, and constantly monitor our discharge with government-linked systems. We provide official reports as proof.

I’ve seen the damage that irresponsible factories can do. The rivers near old denim towns tell a sad story of neglect.

That's why building a state-of-the-art water treatment facility wasn't an option for me; it was a moral requirement when I founded DiZNEW.

This system protects the local environment, and just as importantly, it protects your brand’s integrity. There can be no compromise on this.

What treatment systems do you use to remove harmful chemicals?

Indigo dye and washing chemicals are harsh. You worry that these toxins are just being dumped into a river, creating an environmental disaster that is tied to your brand's name.

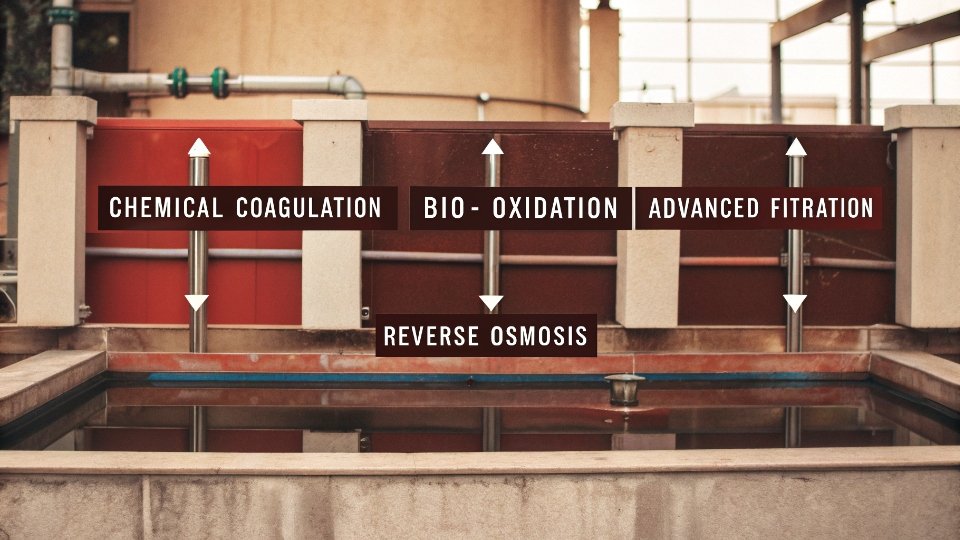

We use a three-step process: chemical coagulation to remove solids, bio-oxidation3 to break down organics, and advanced filtration like reverse osmosis4 to purify the water, ensuring it is clean.

Removing chemicals from denim wastewater is a complex process. You can't just use one simple filter.

We've engineered a multi-stage system where each step targets different types of pollutants, ensuring the final water we discharge is safe for the environment. It works like this:

| Stage | Technology Used | What It Removes |

|---|---|---|

| 1. Primary Treatment | Coagulation | We add agents that make suspended solids, loose dye particles, and other large pollutants clump together so they can be easily filtered out. |

| 2. Secondary Treatment | Bio-Contact Oxidation | The water then flows into tanks filled with microorganisms. These "good bacteria" eat the harmful organic compounds, breaking them down naturally. |

| 3. Tertiary Treatment | Advanced Filtration | For the final polish, we use systems like activated carbon filters and even reverse osmosis4 to remove the last traces of color and the most stubborn chemicals. |

This comprehensive approach allows us to dramatically reduce pollutants. For example, our process can lower the Chemical Oxygen Demand (COD)5 from over 400 mg/L down to less than 55 mg/L, exceeding regulatory standards.

Can you actually recycle the wash water for multiple cycles?

Denim production uses massive amounts of water. You want to reduce this footprint, but you're skeptical that recycled water is clean enough for high-quality production without hurting the final wash.

Yes. Our advanced "Ultrafiltration6 + Reverse Osmosis" system purifies water so it's clean enough for all washing and even dyeing processes. We can achieve 100% water recycling7 for certain finishing processes.

Recycling water is one of the most impactful things we can do for sustainability. It’s not a dream; it’s a reality in our factory.

We collaborated with top engineers to build a system specifically for reusing denim finishing water.

After our primary treatment, the water goes through a deep purification process using Ultrafiltration (UF) and Reverse Osmosis (RO) membranes.

This is the same technology used to desalinate seawater. It pushes water through incredibly fine pores under high pressure, leaving virtually all impurities behind.

The resulting water is so pure that its quality meets the strict requirements for reuse in our washing and dyeing machines.

For example, Levi's has successfully used this technology in its partner factories in China to produce collections using 100% recycled water, saving millions of liters.

This is not a compromise on quality; it's a testament to what's possible with the right technology and commitment.

How do you monitor the water you discharge?

A factory can have a great treatment system, but if no one is watching, it might not be running correctly. You need absolute assurance that their discharged water is clean every single day.

We use a dual monitoring system. Automated 24/7 online sensors are connected directly to the environmental agency, and we conduct regular manual lab tests for complete and accurate verification.

For us, monitoring is about total transparency and accountability. We don't just hope our system is working; we prove it constantly with a two-part approach. First, we have an automated online monitoring8 system installed at our final discharge point. This equipment runs 24/7, measuring key indicators like pH, Chroma (color), and COD in real-time.

Critically, this system is directly linked to the local and national environmental protection agency's digital platform. The government sees the same data we see, exactly when we see it.

If any metric ever goes out of compliance, an alarm is triggered automatically. Second, we back this up with regular manual testing. Our on-site technicians take samples and run them through our lab.

We also hire independent labs to test for a wider range of substances like heavy metals. This dual system leaves no room for error and ensures we are always compliant.

What reports can you provide to confirm environmental compliance?

You need to prove your sustainability claims to big retailers and a skeptical public. Without official, verifiable documents, your words are just marketing and lack real credibility.

We provide a full compliance package, including our government-submitted Pollutant Discharge Permit reports, internal self-monitoring data, and official reports from independent third-party and government inspections.

Claims mean nothing without proof. We provide a complete paper trail to validate our environmental performance, giving you the documentation you need for your own corporate responsibility reports and retailer requirements.

This package includes several layers of verification. The most important document is our Pollutant Discharge Permit9 Execution Report.

This is a mandatory report we submit to the government on a monthly and quarterly basis, detailing our water usage, pollutant output, and the operational status of our treatment facilities.

We also compile our daily logs into a Self-Monitoring Report, which shows the raw data from both our online sensors and manual lab tests.

Finally, and perhaps most valuable for your partners, we have Third-Party Inspection Reports10. These are audits and water quality tests conducted by accredited independent institutions and by the environmental agency11 during their surprise on-site inspections. Having a clean report from these inspections is the ultimate proof of compliance.

Conclusion

Our advanced water treatment, recycling, and transparent monitoring are not just features; they are proof of our commitment. We give you the confidence that your jeans are made responsibly.

-

Explore the advantages of sustainable jeans to understand how they contribute to environmental protection. ↩

-

Learn about the technology behind wastewater treatment systems and their importance in manufacturing. ↩

-

Explore how bio-oxidation utilizes microorganisms to break down harmful compounds in water. ↩

-

Learn about reverse osmosis technology and its effectiveness in purifying water for reuse. ↩ ↩

-

Understand the significance of COD in assessing water quality and treatment efficiency. ↩

-

Discover how Ultrafiltration technology helps in purifying water and its applications in industries. ↩

-

Discover the environmental benefits of water recycling in industrial processes. ↩

-

Explore how automated monitoring systems enhance the efficiency and reliability of wastewater treatment. ↩

-

Explore the significance of Pollutant Discharge Permits in regulating industrial wastewater. ↩

-

Learn about the role of independent inspections in ensuring compliance and credibility. ↩

-

Understand the critical role of environmental agencies in regulating and monitoring pollution. ↩