You see pants labeled "twill," "canvas," or "chambray," and they look a lot like jeans. This makes you wonder what the big deal about denim is. Why does it get its own category?

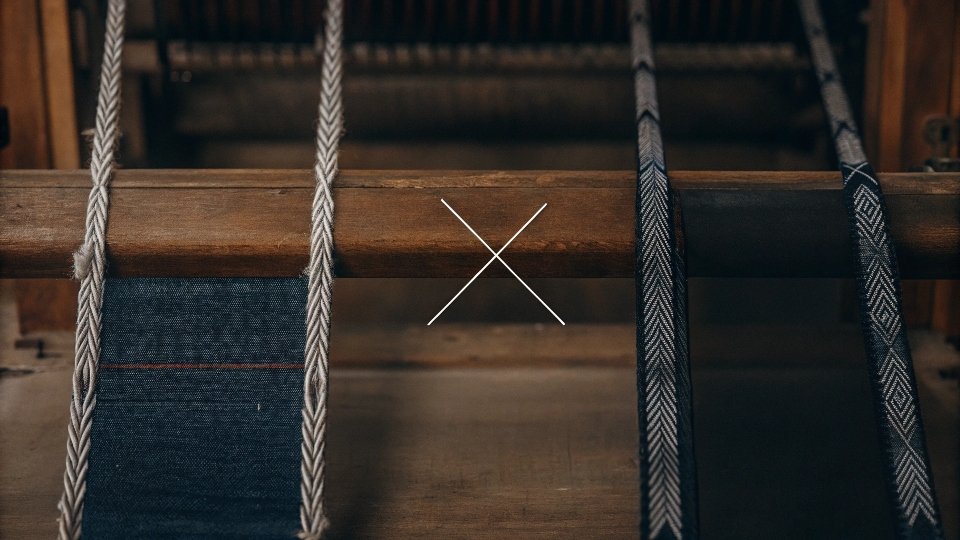

The real difference is how it's made. Denim is a sturdy cotton twill fabric defined by a diagonal weave and a unique dye process where indigo-dyed warp threads are woven with white weft threads, creating a fabric that is blue on its face and lighter on the back.

Over my two decades in this business, I've worked with countless fabrics. But denim is special. Its construction is what gives it the strength to be workwear and the character to become a fashion icon.

When a designer like Dean sends me a spec sheet, we don't just talk about color; we talk about the weight, the weave, and how the fabric will wear over time. To truly appreciate your favorite pair of jeans, you need to understand the material itself. It’s a story woven in cotton.

What really separates denim from other cottons?

You feel a pair of khaki pants and a pair of blue jeans. They are both made of cotton, but they are clearly not the same. You wonder what specific construction detail creates this difference.

The main difference is the weave and the dye. Denim uses a 3x1 twill weave that creates diagonal lines. More importantly, only the vertical (warp) threads are dyed blue, while the horizontal (weft) threads remain white. This is unique to denim.

My entire world revolves around this specific construction. Denim is a "warp-faced" textile. This means when we weave it, the horizontal thread (the weft) passes under two or more vertical threads (the warp).

This creates the visible diagonal ribbing1 that distinguishes it from a simple, grid-like fabric like cotton duck or canvas. The insight in your question is spot on. For classic blue jeans, we take batches of cotton yarn.

One batch is kept in its natural, off-white state. This will be our weft yarn. The other batch, the warp yarn, is dyed that deep, iconic indigo blue. When they are woven together, more of the blue warp threads are visible on the front surface, which is why jeans are blue on the outside.

But if you look inside your jeans, you’ll see it’s much lighter. That is the white weft yarn showing through. This combination is the secret to everything.

| Fabric | Weave Type | Dye Method | Key Characteristic |

|---|---|---|---|

| Denim | Twill | Warp yarns dyed (indigo), weft yarns left white. | Diagonal lines, fades well. |

| Canvas | Plain | Often piece-dyed (dyed after weaving). | Grid-like, very stiff. |

| Khaki | Twill | Usually piece-dyed. | Diagonal lines, uniform color. |

| Chambray | Plain | Alternating colored and white yarns. | Grid-like, lightweight. |

Is denim always blue?

You walk into a store and see "denim" jackets in black, olive green, and white. This makes you question the classic definition. If it's not blue, you wonder if it can still be called denim.

No, denim is not always blue. While traditional denim is dyed with indigo, the term "denim" technically refers to the fabric's diagonal twill weave, not its color. It can be made in any color, with black being the second most popular.

This is a great question that gets to the heart of how we define fabrics in the industry. While 99% of people associate denim with that iconic indigo color, the fabric's true identity is its structure.

At my factory, we produce denim in many shades. Indigo is king because of how beautifully it fades. The dye molecules don't fully penetrate the cotton, so they chip away with wear, creating a personal story on your jeans.

For black denim, we typically use a sulphur dye2. This dye behaves differently. It saturates the yarn more deeply, so it fades less dramatically, usually to a soft grey. When a client wants a pair of black jeans that will stay black for a long time, we use a "reactive dye" that chemically bonds to the cotton. We can also use other dye colors for the warp yarns to create red, green, or brown denim. The one constant is the diagonal twill weave3. Without that, it’s just another piece of cotton twill. So, while blue is the heritage, the weave is the soul.

How to tell if something is denim?

You're looking at a pair of pants that look like jeans but feel a bit too soft or light. You're not sure how to verify if it's the real deal or just a convincing imitation.

The easiest way to tell is to look at the fabric up close. True denim will have visible diagonal lines in its weave. Then, check the inside of the garment; it should be noticeably lighter in color than the outside.

When I train new people at DiZNEW, I teach them to use their eyes and hands to identify true denim. You can do the same thing in any store. I call it the "Denim Confirmation Test." It’s three simple steps.

When I train new people at DiZNEW, I teach them to use their eyes and hands to identify true denim. You can do the same thing in any store. I call it the "Denim Confirmation Test." It’s three simple steps.

First, look for the diagonal4. Get your eyes close to the fabric. Do you see fine diagonal lines running across the surface? If you see a simple, square grid pattern, it's likely a plain-weave fabric like chambray or canvas, not denim. This diagonal pattern is the number one sign.

Second, do the flip test5. Turn the cuff of the pants or the hem of the jacket inside out. Is the color on the inside significantly lighter than the outside? As we discussed, this is because the undyed white weft threads are more visible on the back. If the color is identical on both sides, it's probably a piece-dyed twill, not authentic denim.

Third, trust the feel. True denim, even with a little stretch, should feel substantial and sturdy. It’s a fabric born from workwear. If it feels as thin and light as a dress shirt, it’s almost certainly chambray, which is designed to look like a lightweight denim but lacks its durability.

What is the natural color of denim?

You hear about "raw" denim and see its deep, dark blue color. It's easy to assume this is the fabric's original, untouched state. But that's not the whole story of its origin.

The true natural color of denim is the color of cotton itself: a creamy, off-white. This undyed fabric is called ecru denim. The iconic blue color is only created when the warp yarns are dyed with indigo before weaving.

This goes right back to the beginning of the process. Before there is any blue, there is just cotton. After cotton is harvested and cleaned, it is spun into yarn.

This raw yarn is a beautiful off-white color, which we in the industry call "ecru6." My Chinese suppliers have a great term for it: "Ben Baisha," which means "natural white yarn7." This is the foundation.

To make classic blue jeans, this is the yarn we use for the weft—the horizontal threads. We take another batch of this same ecru yarn and send it for dyeing, soaking it in vats of indigo to get that deep blue.

We then weave the blue warp threads with the ecru weft threads. So, in a way, every pair of blue jeans is half-blue and half-natural white. Making jeans from 100% ecru denim, where both the warp and weft are left undyed, is also a beautiful style.

It creates a pair of "natural" jeans that are prized for their pure and organic look, showing the fabric's texture without any color to hide behind.

Conclusion

The true essence of denim is its diagonal twill weave and unique warp-dyeing process. This construction separates it from all other fabrics, creating its legendary strength and iconic fading potential.

-

Exploring diagonal ribbing will enhance your knowledge of fabric textures and their impact on garment design. ↩

-

Explore this link to understand the unique properties of sulphur dye and its impact on denim's color and longevity. ↩

-

Discover the significance of diagonal twill weave in denim, as it defines the fabric's structure and quality. ↩

-

Understanding this key step helps you distinguish authentic denim from other fabrics, ensuring quality in your purchases. ↩

-

This test is crucial for verifying denim authenticity, guiding you to make informed choices when shopping. ↩

-

Explore this link to understand the significance of ecru in textiles and its impact on fashion. ↩

-

Discover the benefits and applications of natural white yarn in various textile products. ↩